Fire Rated Ductwork Solutions

- ホーム

- »

- Fire Rated Ductwork

Leading Fire-Safe Duct Solutions in China

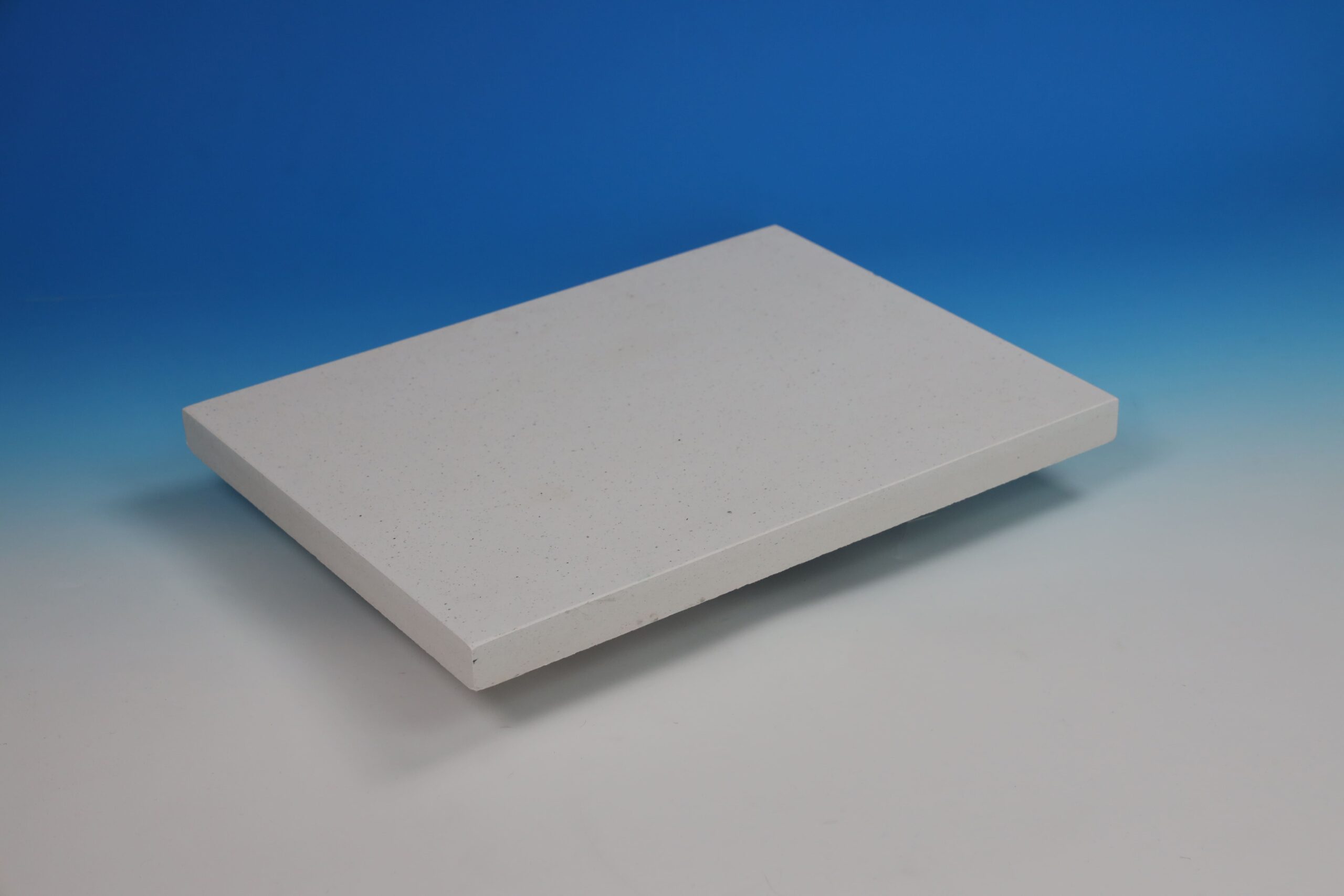

In the bustling industrial landscape of China, FireSafe stands at the forefront as a leading manufacturer and supplier of high-quality fireproof boards. Our products form the backbone of fire-rated duct systems, playing an essential role in fireproof partitions extensively used in buildings, both civil and industrial, across the world.

Our fire-rated duct solutions offer unparalleled customization, efficiency, and reliability. This enables us to meet the diverse requirements of our clients and provide unrivaled passive fire protection.

Passive Fire Protection One-Stop Solution

all you need to know about fire rated ductwork

Why do we need fire rated ductwork?

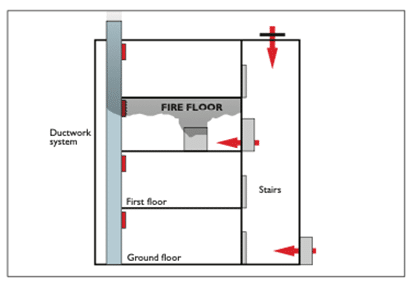

Fire-rated ductwork is crucial for enhancing the fire safety of HVAC systems in homes and offices. These specialized ducts prevent the spread of fire and smoke, providing a vital barrier that protects occupants and property. By maintaining air supply and blocking toxic gases, they ensure safer evacuation routes and limit fire damage.

In a fire, fire-rated ducts continue to supply fresh air while blocking toxic gases and flames from moving between building zones. This crucial function helps maintain a safer environment, offering more time for evacuation and reducing fire-related risks.

Implementing fire-rated ductwork is essential in modern buildings, as it significantly enhances safety by limiting fire damage and protecting lives. This makes our indoor environments not only comfortable but also secure.

Table of Contents

What are the different types of Fire Rated Ductwork ?

Fire-rated ducts, integral components of any building’s safety strategy, fall into two main categories based on their functions: smoke extraction ducts and fire-rated ventilation ducts.

Smoke extraction ducts

Primarily designed to maintain ventilation during a fire, smoke extraction ducts serve the vital role of removing smoke from the building, thereby facilitating safer and more efficient emergency evacuations. Depending on the driving force behind the ventilation, these ducts can be further divided into natural ventilation ducts, which utilize the natural flow of air, and mechanical ventilation ducts, which employ mechanical systems for air movement.

Fire rated ventilation ducts

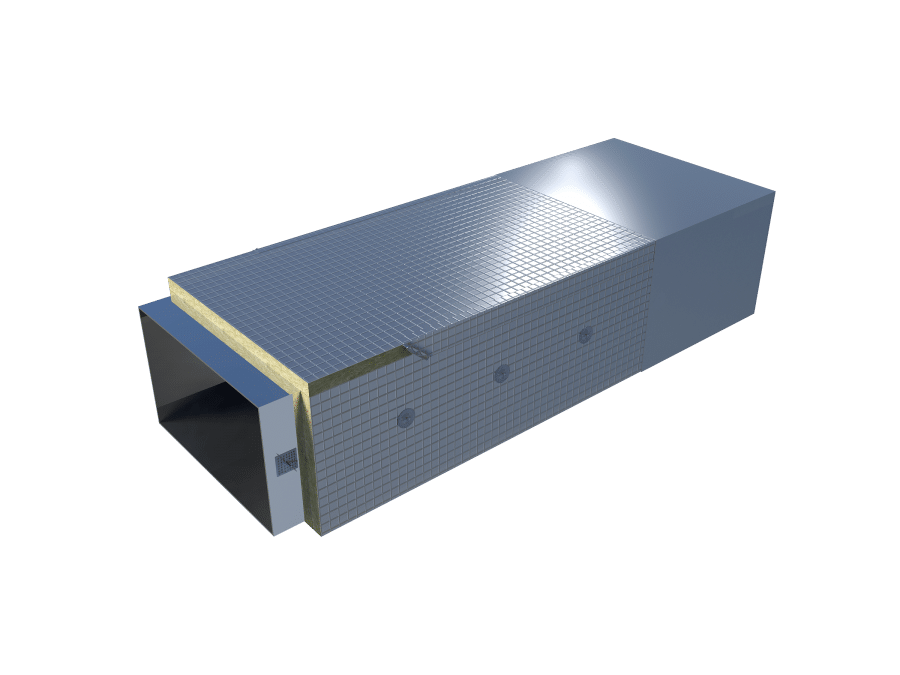

These ducts play a critical role in preventing the spread of fire between different compartments of a building. Traditional metal sheet ducts, when exposed to fires, may deform and heat up, becoming unsuitable for use in fire compartments. Fire-rated ventilation ducts, on the other hand, are designed to withstand high temperatures without compromising their structure or functionality, making them suitable for non-grease applications.

Whether they are wrapped in protective material or built to withstand four fire conditions, these air ducts go above and beyond to ensure safety during fires. Understanding the different types of fire-rated ducts is the first step towards a safer, more secure building.

When it comes to fire safety in buildings, the structural design of ducts plays a significant role. We can classify these essential components into self-supporting ducts and cladding ducts.

Self-supporting ducts

A marvel of engineering, self-supporting ducts integrate structure and function into a single system. The easy installation process and excellent performance make these ducts a preferred choice for many. However, they come with a higher price tag and demand stringent material standards.

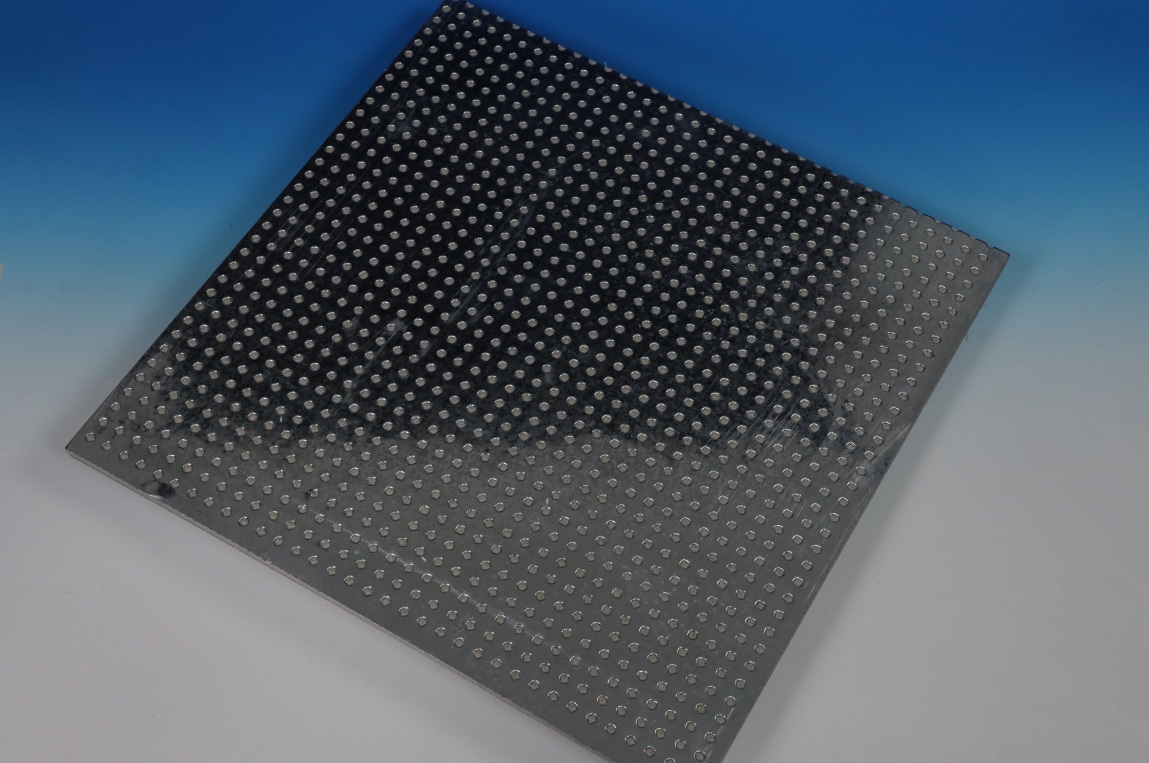

Cladding ductworks

An economical alternative, cladding ducts involve the addition of rigid or flexible cladding, such as ceramic fire wrap, to the exterior of typical metal sheet ducts. This cladding shields the ducts from the impact of flames under fire conditions. The construction process for these ducts takes into account the original structure of the metal sheet ducts, which adds complexity.

What is the Decoding Fire Test Procedures ?

A thorough fire test is crucial to evaluate the insulation performance and integrity of ducts, whether they are horizontally or vertically oriented. Commonly followed test methods include ISO 6944, EN 1366, BS 476: Part 24, or AS 1530. Part 4. While test details vary across these standards, the core principles and methods remain consistent, ensuring every tested duct is in accordance with stringent safety norms.

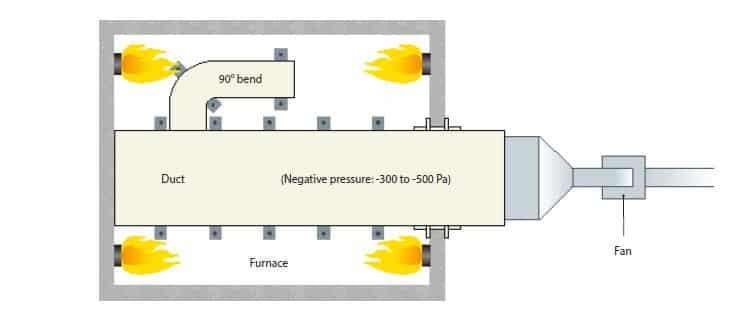

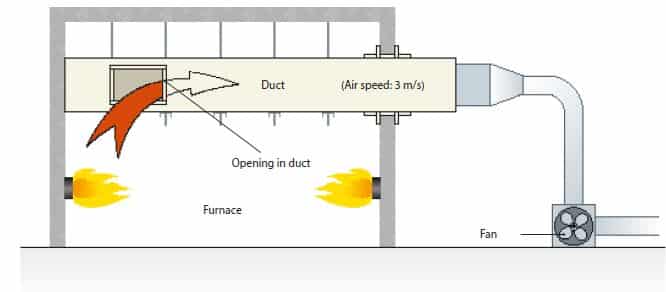

Central to the fire test procedure is the exposure of duct samples to varying fire conditions. A Type A duct sample is exposed to an external flame, while a Type B duct sample faces both external and internal fires. A standard fan generates differential pressure and airflow rate, allowing evaluators to assess the duct’s fire performance with the fan in both operating and non-operating states.

DUCT A

DUCT b

Integrity (E)

A duct fails the integrity test if cracks, holes, or openings appear in the duct, often at the splice, compromising its seal.

Insulation (I)

Failure in insulation performance is determined if the temperature rise on the outer surface of the external ducts exceeds an average of 140°C or a peak of 180°C.

Smoke leakage (S)

Leakage should not surpass 5 cubic meters per hour for every 1 square meter of the duct's internal surface area.

Reduction in cross-section

The internal dimensions of the ductwork (width and height for rectangular ducts, diameter for round ducts) must not be reduced by more than 10% during the test period.

Mechanical stability

The mechanical stability test checks if the duct maintains its smoke extraction or fire protection function despite exposure to flame. If it collapses, it is deemed to have failed the test.

Key Influences on Fire Test Results

Factors significantly impacting fire test results include the boards and adhesives.

Fire Board: The performance of the board itself is the most influential factor on the fire test results, whether it is a self-supporting duct or a cladding duct.

Consider these THREE KEY POINTS:

Fire resistance of the boards

The board’s fire resistance capacity is the most influential factor on the test results. For example, calcium silicates can withstand up to 1000℃, aluminum silicate wool exceeds 1000℃, stone wool manages about 400-500℃, and glass wool is around 300℃. When the fire resistance requirement exceeds 60 minutes, combining different materials becomes necessary. With the right combination, a fire resistance level of 240 minutes (Integrity) can be achieved.

What is the thickness of a fire-rated duct?

A fire-rated duct should be constructed with a single skin, having a total thickness not exceeding 2mm. This measurement includes the intumescent coating, which is essential for enhancing fire resistance. The intumescent coating expands when exposed to heat, providing additional protection. Therefore, the overall thickness of the fire-rated duct, including the coating, ensures compliance with safety standards while maintaining structural integrity.

Additional Considerations: The thickness of the chosen material is crucial in determining fire resistance. However, overly thick materials may compromise the practicality of the system. A comprehensive duct system design should include elements like smoke dampers and supporting construction for both horizontal and vertical ducts to ensure optimal performance and safety.

Thermal Conductivity

The material’s thermal conductivity plays a vital role. A higher thermal conductivity will cause the temperature of the backfire surface to rise faster, potentially exceeding 140°C (average). Therefore, careful consideration must be given to this factor.

Adhesives:

The joints of self-supporting ducts, particularly in rectangular ducts, often become weak points during fire tests. Ordinary adhesives may not withstand prolonged fire exposure, leading to potential failure and allowing flames to escape. Consequently, it’s essential to use inorganic adhesives capable of enduring prolonged fire exposure.

For more information about achieving optimal fire protection and fire inside resistance with the right materials and ceramic fire wrap, feel free to consult with us.

Simple and Efficient Installation Guide for Fire Rated Ducts

FireSafe products are designed with user-friendliness and straightforward installation in mind. For the FireSafe-500 duct system, the equipment you’ll need includes a bar saw, a nail gun, an air pump, matching nails, FireSafe-500 boards, and FireSafe-1808 adhesive. Our products come with detailed instructions to guide you through each step, and our team is always ready to assist you further.

Here’s why FireSafe products stand out:

Versatility: Our products are well-suited for both self-supporting and cladding duct applications. Whether you’re installing a horizontal or vertical duct, FireSafe provides the right solution.

Efficiency: Our single-layer construction meets all fire resistance requirements, ensuring the barrier necessary to protect from fire inside and achieve the desired level of safety in non-grease applications.

Durability: Our products are dimensionally stable and resistant to moisture, making them ideal for use in various environments and conditions, including floors and walls.

Easy Customization: The FireSafe-500 boards are easy to cut, allowing for custom installations that fit your specific needs.

Lightweight Profiles: Our products are easy to handle and install, reducing labor effort and installation time.

Low Maintenance: With a smooth surface and solid structure, FireSafe products require minimal upkeep, maximizing the protection they offer over time.

Remember, the right installation of a fire-rated duct system is crucial for its performance. For additional guidance, including information on ceramic fire wrap and test methods, don’t hesitate to contact us.

Frequently Asked Questions

We have compiled the most frequently asked questions about our products for fire rated ductwork here for your convenience, but please feel free to contact us if you have any additional questions.

Contact our technical experts today with the details of your design and we will recommend the right product for you based on our experience.

FRL stands for Fire Resistance Level. It refers to the ability of building components to withstand fire under test conditions for a specific period of time (usually 30 minutes and its multiples, such as 60, 90, 120, or 240 minutes). FRL is determined based on three key properties: structural integrity, thermal insulation, and load-bearing performance.

For example, an FRL of 240 minutes means that after 240 minutes of fire exposure, the building component must meet the standard acceptance criteria for all three properties. FRL is an essential factor to consider in passive fire protection design, ensuring that buildings can resist and contain fires, providing precious time for occupants to evacuate and for firefighters to control the blaze.

Yes. We can supply you with all the main materials and accessories you need during the installation of the fire duct.

Yes, you can develop your M&E service enclosures and cable protection systems with reference to the ventilation duct system. However, there are some slight differences to consider for M&E service enclosures and cable protection systems:

(a) Ensure the cables continue to function during exposure;

(b) Maintain the temperature on the cable sheath below 150°C.

These requirements are specified in the German standard DIN 4102, ‘Fire Behavior of Building Materials and Building Components,’ Parts 11 and 12.

Yes. Contact customer service today for a reasonable and precise board quote. Include specific details including but not limited to size, thickness, application and FRL.

For as low as one cube meter of fireproof boards, you can secure your order and we can manufacture and deliver it to you according to your requirements.

It takes us around 15 to 30 business days to produce the fire rated boards. On the other note, the transit time will take 7 to 15 business days. Reach us online for your custom and bulk orders so we can explain the actual turnaround time based on the specific details of your order.

Surely! You can always request a sample before place the bulk order. Sample time usually will take 2-3 days, depends on the specifications you need.

Request a sample now!

Request an Instant Quote for Your Projects!

If you’ve got passive fire protection concerns and specific requirements, it’s time to speak to one of our Industry Experts. We’re glad to answer any questions you may have!