Overview of Fire Protection Systems

A fire protection system is a comprehensive setup designed to detect, control, and extinguish fires, safeguarding people and property.

Fire protection systems are typically categorized into two types: active systems, which include fire detection, alarms, water supply, and smoke control; and passive systems, which cover building layout, fire-resistant materials, and fire partitions. Together, they minimize fire damage and save lives.

Compliance with local fire codes ensures proper design, installation, and maintenance of these systems, which are critical for fire safety.

What is Active Fire Protection?

Active fire protection systems directly intervene or suppress the spread of fire through automatic or manual operation. These systems rely on sensors, detection devices, and fire suppression equipment to detect fires, trigger alarms, or extinguish flames.

Fire Detection and Alarm Systems

The fire detection and alarm system is the core component of an active fire protection system. Its primary function is to detect fires at an early stage and issue timely warnings. The system includes:

Fire detection devices include smoke, heat, flame, and gas detectors. These devices work together to identify fire hazards and trigger alarms:

- Smoke detectors: Detect smoke particles in the air.

- Heat detectors: Monitor rapid temperature changes.

- Flame detectors: Sense ultraviolet or infrared radiation from flames.

- Gas detectors: Identify hazardous gases like carbon monoxide or other flammable gases.

Fire Suppression Systems

Automatic Fire Suppression Systems

Automatic systems extinguish or control fires in their early stages without human intervention. Common types include:

Sprinkler Systems: The most common system in buildings, sprinkler heads automatically spray water when fire is detected. Widely used in residential, commercial, and industrial premises.

Gas Fire Suppression Systems: Ideal for environments where water is unsuitable, such as data centers. These systems release gases like carbon dioxide or nitrogen to lower oxygen levels and extinguish the fire.

Foam Suppression Systems: Used for oil and liquid fires, foam covers the fire, cutting off oxygen and quickly suppressing flames.

Dry Powder Systems: Suitable for electrical and flammable liquid fires, using dry powder to extinguish flames.

Manual Fire Suppression Devices

Manual systems require human intervention to control fires. Common devices include:

- Fire Extinguishers: Portable devices for small fires, available in types like dry powder, carbon dioxide, and foam.

- Hydrant Systems: Water supply points inside or outside buildings, used with hoses for manual firefighting.

- Water Guns and Hoses: Used with hydrants to manually direct water onto fires.

Ventilation, Smoke Extraction, and Evacuation Systems

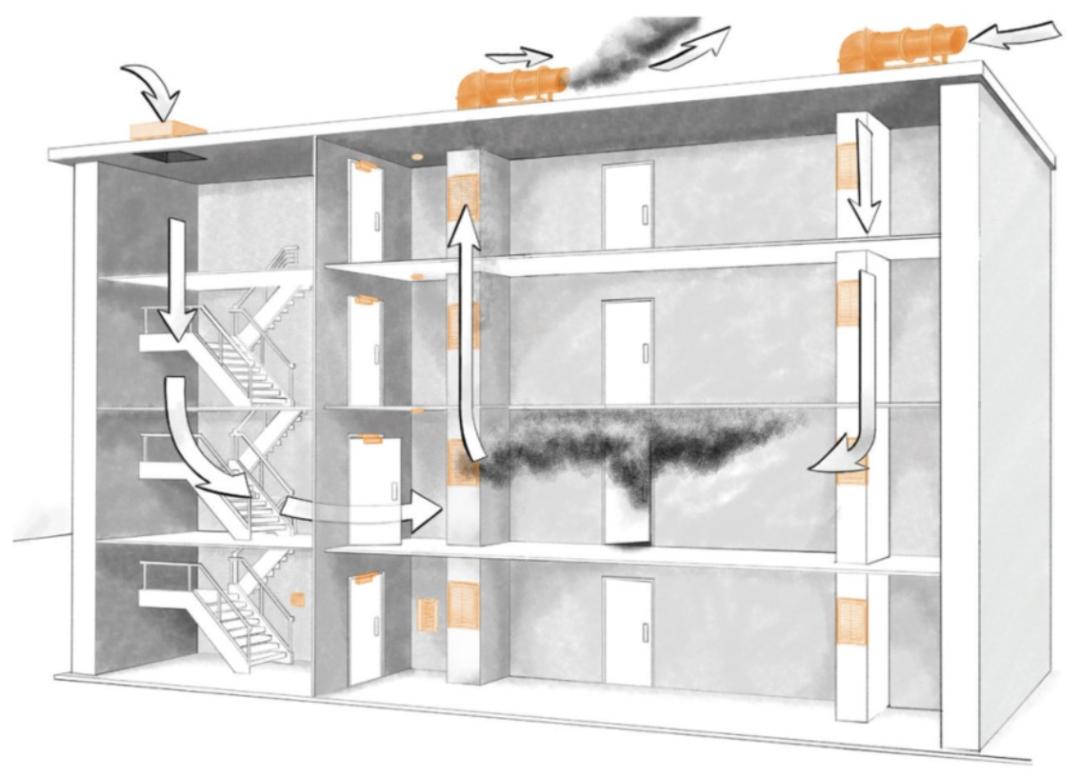

1.Ventilation and Smoke Exhaust System

Smoke from a fire is often more dangerous than the flames themselves, making smoke exhaust systems a crucial part of active fire protection. These systems, whether manually or automatically activated, remove smoke and toxic gases from buildings to improve evacuation conditions. They include:

- Mechanical Smoke Exhaust System: Uses fans and ventilation ducts to actively expel smoke from the building.

- Natural Smoke Exhaust System: Utilizes openable windows or vents at the top or sides of the building to allow smoke to rise and escape naturally.

2.Emergency Evacuation System

Emergency evacuation systems ensure that people can quickly and safely exit a building during a fire. The system includes:

- Emergency Lighting System: Provides sufficient lighting during power outages to help people locate safe exits.

- Evacuation Instruction Signs: Clearly mark escape routes and exits to guide personnel away from danger.

- Sound and Light Alarm System: Uses audible alarms and flashing lights to alert people and prompt immediate evacuation.

3.Fire Linkage Control System

The fire linkage control system coordinates multiple protective devices during a fire. Upon detecting a fire, it can automatically close fire doors, activate smoke exhaust fans, and open fire shutters to ensure all fire prevention facilities work together, minimizing the damage caused by fire.

Why Active Fire Protection is Important

Active fire protection systems detect fires early and issue immediate alarms, helping to quickly extinguish the fire before it spreads. These systems not only reduce property damage but also provide crucial time for safe evacuation, protecting lives.

With sensors and detectors, active fire protection systems continuously monitor the environment for fire risks and respond promptly. Many systems activate automatically when a fire is detected, eliminating the need for human intervention and increasing firefighting efficiency. Additionally, modern systems can integrate with other building safety measures (e.g., fire doors, smoke extraction systems) for more comprehensive fire protection.

What is Passive Fire Protection?

Passive fire protection involves building materials and structural designs that prevent the spread of fire and protect people and property. Unlike active fire protection, passive systems don’t require activation; they rely on the fire-resistant properties of the materials themselves. The primary goal is to contain the fire within a specific area, allowing more time for evacuation and rescue while minimizing structural damage.

Purpose of Passive Fire Protection

The purpose of passive fire protection is to slow the spread of fire and reduce damage through building design and structural precautions. It helps safeguard the building, protect people and property, and provides more time for evacuation and rescue.

Passive fire protection works automatically during a fire, without needing external activation, electricity, or sensors. It functions as long as the building structure remains intact and typically requires minimal maintenance. By creating fire-resistant barriers and delaying the spread of flames and smoke, passive fire protection significantly reduces the risk of fire spreading, complementing active fire protection systems for comprehensive safety.

Why is it Important to Develop a Passive Fire Protection Strategy?

A passive fire protection strategy provides essential safety during a fire, minimizing harm to people, buildings, and property. Its importance lies in several key areas:

Reducing Fire Risk and Spread: Passive fire protection helps slow the spread of fire through fire-resistant materials and compartmentation. This containment limits fire damage to specific areas, making firefighting more manageable and reducing overall fire impact.

Protecting Lives: Ensuring occupant safety is paramount. Passive fire measures like firewalls, doors, and partitions delay the spread of fire and smoke, allowing more time for safe evacuation. This increases survival rates during a fire emergency.

Maintaining Structural Integrity: Fire can weaken structural elements, especially steel, leading to potential collapse. Passive strategies, using fire-resistant coatings and panels, protect load-bearing structures, preserving the building’s stability and minimizing damage.

Reducing Property Damage: By containing the fire, passive fire protection limits damage to equipment, furniture, and other assets, protecting critical areas and reducing the loss of valuable property.

Simplifying Post-Fire Restoration: Limiting fire spread reduces the extent of necessary repairs, making reconstruction faster, less costly, and less resource-intensive, speeding up the process of returning the building to use.

Complementing Active Fire Systems: While active fire protection (e.g., sprinklers, smoke detectors) is effective, it has limitations, such as potential failure. Passive systems, which don’t rely on electricity or sensors, offer continuous protection, serving as a backup to active systems.

Long-Lasting and Low Maintenance: Once installed, passive systems like firewalls and fire-resistant materials provide continuous protection with minimal maintenance, making them a cost-effective solution for long-term fire safety.

Handling Unforeseen Fires: Even with modern fire detection and suppression systems, fires can still occur. Passive fire protection adds an extra layer of defense, ensuring more time for evacuation and rescue in worst-case scenarios.

Compliance with Codes and Standards: Many building codes require passive fire protection, especially in high-risk structures like high-rises and industrial facilities. Developing a passive fire strategy ensures compliance with regulations, avoiding legal issues and ensuring safety standards are met.

Role of Passive Fire Protection Systems

Passive fire protection systems work by utilizing structural design and fire-resistant materials to slow the spread of fire, protect building integrity, and minimize loss of life and property. The key roles of passive fire protection include:

Fire Separation and Zoning: Firewalls, fire doors, and partitions create isolated fire zones, preventing the spread of fire and smoke. These barriers confine fire to specific areas, allowing more time for evacuation and firefighting.

Extending Evacuation Time: Fire-resistant materials applied to structural elements like steel beams and walls slow fire damage, providing crucial time for occupants to evacuate. Intumescent coatings, for example, expand under heat to insulate key components.

Smoke Control: Sealed fire doors and partitions limit the spread of smoke, keeping escape routes clear and reducing the risk of smoke inhalation during evacuation.

Protecting Structural Integrity: Fire-resistant coatings and panels help preserve load-bearing structures during a fire, preventing collapse and enabling post-fire recovery. These materials provide insulation that delays heat damage to critical components.

Sealing Penetration Points: Fire-resistant sealants and materials block gaps around pipes, cables, and ducts to prevent fire and smoke from spreading through these vulnerable areas.

Reducing Post-Fire Repair Costs: Effective fire containment reduces fire damage to specific areas, minimizing overall repair time and costs. This containment ensures that unaffected parts of the building remain intact.

What Does a Passive Fire Protection System Involve?

Passive fire protection systems rely on fire-resistant materials and structural design to minimize fire damage by slowing its spread, creating fire barriers, and protecting the building’s structure. Unlike active systems, passive fire protection doesn’t require activation; it works automatically through its built-in properties during a fire. Key components of a passive fire protection system include:

Fire Escape Routes

Fire escape routes are designed to provide a safe path for people to evacuate from a fire to a secure location. Proper planning of escape routes is critical to ensuring quick and safe evacuation during an emergency.

Fire Doors

Fire doors, installed at entrances of passages, staircases, or rooms, automatically close during a fire to block the spread of flames and smoke, protecting evacuation routes and limiting fire damage.

Fire Stopping

Firestopping seals gaps and penetrations (e.g., around cables, ducts, pipes) to prevent the spread of fire through walls, floors, and ceilings. This system uses various materials such as fire-resistant boards, fire sealants, and fireproof packages to ensure that openings remain fireproof. Firestopping is crucial for maintaining the integrity of fire-rated compartments and preventing fire from traveling through vulnerable areas.

Intumescent Fire Protection

Intumescent fire protection is a coating applied to structural steel, expanding when exposed to high temperatures to form an insulating layer. This layer delays the fire’s attack on the structure, helping maintain its integrity. Intumescent coatings also provide a smooth, aesthetically pleasing finish and help prevent corrosion. They are widely used in structural steel buildings due to their efficiency and relatively thin application (350 to 700 microns).

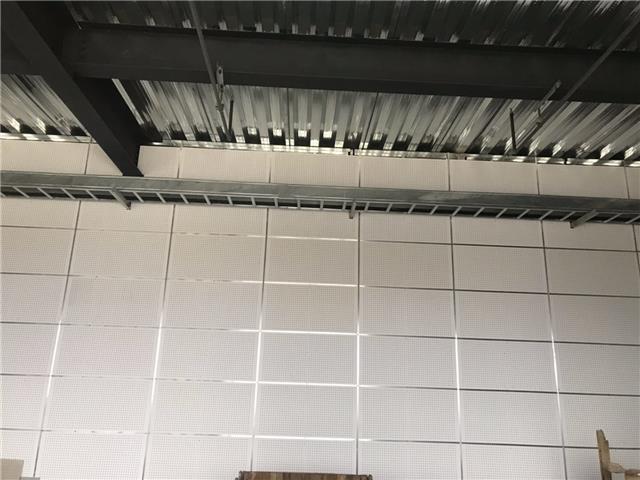

Smoke and Ventilation Ducts

Smoke poses a significant threat in fires. Smoke exhaust and ventilation ducts are essential for maintaining air quality and removing smoke during a fire, ensuring safe evacuation routes. Fire-rated ductwork plays a critical role by blocking toxic gases and flames while maintaining structural integrity under high temperatures. To learn more about fire-rated ductwork solutions and their importance in fire protection, visit FireSafe’s Fire-Rated Ductwork Solutions.

Fire Compartments

Fire compartments divide a building into separate areas using fire-resistant structures. In the event of a fire, these compartments contain the fire within a specific zone, protecting other areas and reducing fire spread.

Structural Protection

Structural protection includes measures like fireproof coatings, fire-resistant walls, and fire doors that enhance a building’s ability to resist fire. These systems help maintain the building’s integrity during a fire, ensuring safe evacuation and minimizing property damage.

Fire Partitions

Fire partitions, including fire walls, doors, and windows, are structural elements that divide a building into fire zones. They slow the spread of fire and smoke, protect evacuation routes, and increase the time available for firefighting operations.

Fire Curtains and Ceiling Barriers

Fire curtains are made from fire-resistant fabrics and are installed in large openings like lobbies and stairwells. These curtains are automatically deployed when triggered by the fire alarm system, providing protection without obstructing daily use. Ceiling barriers, made from materials like calcium silicate, prevent fire and smoke from spreading through ceiling spaces.

Passive Fire Certification

Passive fire certification verifies the fire performance of materials and systems to ensure they meet regulatory standards. This certification confirms that products will effectively protect people, property, and building structures during a fire. Typically conducted by third-party organizations, certification assesses fire resistance and smoke insulation.

Main Purpose of Passive Fire Certification

- Ensure product quality and performance.

- Comply with legal and regulatory requirements.

- Enhance building safety and provide time for evacuation.

- Reduce liability risks for developers and owners.

Common Products Certified for Passive Fire Protection

- Firewalls and Fire Doors: Tested for resistance to high temperatures and flames, preventing fire and smoke penetration.

- Fire-Resistant Coatings and Materials: Protects structural integrity by delaying failure at high temperatures.

- Fire-Resistant Glass: Prevents flame and smoke from passing through, maintaining its integrity during a fire.

- Fireproof Plugging Materials: Seals penetrations like cables and pipes to block fire and smoke spread.

- Fire-Rated Rolling Doors: Tested for their ability to quickly form a fire barrier.

- Fire Seals: Expands in case of fire, sealing gaps to block flames and smoke.

Common Test Items for Passive Fire Certification

Fire Resistance Test: Measures how long a product withstands high temperatures.

Thermal Insulation Test: Assesses a material’s ability to prevent heat transfer.

Smoke Barrier Test: Evaluates the material’s effectiveness in blocking smoke spread.

Integrity Test: Tests the stability of a material or structure under fire conditions.

Common Fire Protection Standards

Passive fire protection systems must meet various international and regional standards to ensure their effectiveness in protecting buildings and people from fire. Some of the most widely recognized standards include:

EN Standard (Europe): EN 1363-1 is the standard for fire resistance testing, outlining general principles for evaluating how building elements perform under fire exposure. This standard helps ensure fire safety across Europe. You can find more details at BSI Group.

UL Standard (U.S.): UL 263 is one of the primary standards for fire testing in the United States, developed by Underwriters Laboratories. It covers fire tests for building materials and structural components, ensuring they meet required safety benchmarks during a fire.

BS Standard (UK): BS 476 is the British standard for fire testing and protection, providing guidelines for how materials and structures should perform in a fire to ensure safe evacuation and property protection.

GB Standard (China): China’s fire safety regulations include GB 50016, the “Fire Protection Code for Building Design,” and GB 14907, which focuses on fireproof coatings for steel structures. These standards ensure that materials and construction methods comply with national fire safety requirements.

Difference Between Active and Passive Fire Protection

Active and passive fire protection are two key elements of a fire protection system, differing in how they function, trigger, and are applied. Here’s a breakdown of their main differences:

| Aspect | Active Fire Protection | Passive Fire Protection |

|---|---|---|

|

Working Principle

|

Uses sensors and detectors to identify fires and activate fire suppression systems.

|

Uses fire-resistant materials and building design to slow the spread of fire and smoke.

|

|

Triggering Method

|

Requires sensors, detectors, or human intervention to activate.

|

Works automatically without external triggers.

|

|

Main Role

|

Detects and extinguishes fires early to prevent spread and minimize damage.

|

Slows fire spread, provides time for evacuation, and protects structural integrity.

|

|

Response Time

|

Responds quickly, often within seconds.

|

Functions over a longer duration to maintain fire containment.

|

|

Application Scenarios

|

Used in residences, commercial buildings, and industrial facilities for quick suppression.

|

Built into the design of buildings, providing long-term fire resistance.

|

|

Maintenance and Management

|

Requires regular maintenance and testing to ensure functionality.

|

Requires little maintenance; inspected after modifications or damage.

|

|

Cost and Life Cycle

|

Higher initial cost due to complex systems, with ongoing maintenance expenses.

|

Lower maintenance costs, as materials remain effective for the life of the building.

|

|

Fire Protection Effectiveness

|

Can quickly extinguish fires and protect life and property.

|

Controls fire spread and protects the structure, allowing for safe evacuation.

|

How Long Do Fireproofing Materials Last?

The lifespan of fireproofing materials depends on the type of material, its application, and the environment. The fire resistance of materials is typically measured using the Fire Resistance Rating (FRR), indicating how long the material can withstand fire.

Typical Fire Resistance Durations

30 minutes: Used in low-risk areas, such as homes or lightweight partition walls.

60 minutes: Common in medium-risk areas like shopping malls and office buildings.

90 to 120 minutes: Used in high-risk areas such as industrial sites, hospitals, and high-rise buildings.

Fire Resistance Times of Common Materials

Calcium Silicate Board: Offers 2 to 4 hours of fire protection.

Gypsum Board: Typically provides 30 minutes to 2 hours of protection.

Fireproof Coatings: Expands to form an insulating layer, offering protection for 30 minutes to 3 hours, depending on thickness and environment.

Fire Doors: Generally rated to last 1 to 3 hours, with higher grades providing longer protection.

Fire-Resistant Glass: Maintains integrity for 30 minutes to 2 hours, depending on thickness.

Fire Blocking Materials: Seals cable or pipe openings, providing 1 to 3 hours of fire resistance.

Factors Affecting Fireproofing Material Lifespan

Environmental Conditions: High humidity can reduce the effectiveness of some coatings and panels. In these cases, waterproof treatments or suitable materials are necessary.

High Temperature and Corrosive Environments: May shorten the lifespan of fireproofing materials, requiring specialized solutions.

Maintenance: Regular inspections are crucial to maintain performance. Over time, materials like fireproof coatings can deteriorate and may need reapplication.

Fire Intensity: Extreme fire conditions can shorten the fire resistance time of even high-performance materials.

Complementarity of Active and Passive Fire Protection Systems

Active and passive fire protection systems play distinct but complementary roles in ensuring comprehensive fire safety. Together, they provide a layered defense that covers different stages of a fire, from early detection and suppression to long-term structural protection.

Rapid Detection & Fire Containment: Active fire protection systems, such as sprinklers and alarms, quickly detect and suppress fires, minimizing initial damage. Passive fire protection systems, such as fire-rated walls and doors, slow the fire’s spread, maintaining building stability even if the fire isn’t fully extinguished.

Evacuation Time: Active systems provide immediate alerts and fire control, giving occupants time to escape. Passive systems further extend evacuation time by containing the fire and smoke, particularly when the fire isn’t quickly extinguished.

Long-Term Protection: Active systems reduce immediate damage to building structures, while passive systems delay structural failure, ensuring the building’s safety over a longer period during a fire.

Supporting Firefighters: Active systems suppress fires early, aiding firefighters by giving them more control over the situation. Passive systems ensure that fires don’t spread rapidly, creating a safer environment for firefighting efforts.

System Redundancy: If active systems malfunction or are compromised by external factors (e.g., power failure), passive systems provide a fallback, ensuring basic fire protection through fire-resistant materials and designs.

In summary, active systems handle immediate fire suppression, while passive systems contain and slow the fire, protecting the building’s structure and giving people time to escape. Together, they form a robust and reliable fire protection strategy that minimizes fire damage and ensures long-term safety.

The Importance of Working with FireSafe for Passive Fire Protection

FireSafe specializes in providing expert passive fire protection solutions, backed by a team of experienced specialists. Our deep understanding of fire protection technologies and materials allows us to create tailored strategies that meet the unique needs of each client.

FireSafe offers a comprehensive range of fire protection solutions, including fire-rated ductwork, fire partitions, fire blocking materials, and fire doors. For more information on our specific solutions, visit FireSafe Fire-Rated Ductwork Solutions and FireSafe Fire Partitions Solutions. These solutions ensure effective fire isolation, safeguarding people and property in the event of a fire.

What sets FireSafe products apart is their exceptional fire resistance and durability. Our products meet the highest fire protection standards and are rigorously tested to ensure their effectiveness. By utilizing advanced materials and cutting-edge technologies, we not only provide reliable fire protection but also help our clients make long-term safety investments.