Introduction

Definition of Fire Stopping

Fire stopping is a critical fire prevention measure designed to block the spread of flames, smoke, and toxic gases by sealing openings around pipes, cables, and gaps that penetrate fire-rated walls or floor slabs. As a key component of passive fire protection systems, fire stopping effectively prevents the spread of fire, buys valuable time for evacuation and rescue, and helps minimize property damage. This method is primarily used for sealing penetrations, such as cables and pipes, and requires materials that are fire-resistant, high-temperature resistant, and provide excellent sealing properties.

The Role of Fire Stopping in Suppressing the Spread of Fire

Fire stopping plays a crucial role in preventing the spread of fire, smoke, and toxic gases by sealing holes and gaps in buildings. This helps maintain the structural integrity of the building and prevents the fire from spreading from one area to another, effectively slowing down its progression. Fire stopping materials are highly resistant to extreme temperatures and can expand when exposed to heat, creating an insulating barrier. This prevents heat transfer and ignition of areas not directly impacted by the fire, ensuring that fire-rated walls and floor slabs continue to provide protection during a fire.

Passive Fire Protection

The Importance of Fire Stopping in Passive Fire Protection Systems

Fire stopping is crucial in ensuring the isolation of different fire protection zones within a building. By sealing penetration points such as pipelines, cables, and ducts, it prevents the spread of fire, smoke, and heat, slowing the fire’s progression and buying time for personnel evacuation and rescue. This is especially vital in large-scale buildings, as it reduces the risk of casualties. Fire stopping also helps keep toxic fumes from entering evacuation routes, ensuring the safety of occupants.

In addition to safeguarding people, fire stopping maintains the fire resistance of a building’s fire-rated structures, enhancing the overall fire performance. It is a mandatory requirement in building codes across various countries, with the quality of fire stopping directly affecting a building’s fire safety certification, such as UL and EN standards. Meeting these certifications ensures compliance with fire safety regulations, protecting building users.

Furthermore, fire stopping reduces property damage by protecting critical areas and equipment—particularly in high-risk facilities like power rooms and mechanical rooms—thereby preventing secondary disasters. As a part of the passive fire protection system, fire stopping complements active fire protection systems, working together to contain fires and improve overall fire safety efficiency.

Critical Areas Requiring Fire Stopping

1.Pipe Penetrations

Pipes (such as water pipes, gas pipes, sewage pipes, HVAC pipes) and cables often leave openings or gaps when passing through walls, floor slabs, or fire-rated zones. These penetrations, if left unsealed, can become hazardous points where fire, heat, and smoke can easily spread, especially in the case of flammable, explosive, or high-temperature pipes. Therefore, areas like pipe and cable penetrations, cable shafts, and cable trays are critical for fire stopping to prevent the spread of fire and ensure the integrity of fire protection systems.

2.Joints

Joints are areas where different structures or materials within a building connect, often creating gaps or voids. If not effectively fire stopped, these gaps can allow flames, smoke, and toxic gases to spread quickly during a fire. Therefore, applying fire stopping at joints is critical to prevent the rapid escalation of a fire.

3.Top of Walls

The top of walls, where walls meet ceilings or floor slabs, is another key area for fireproofing. Gaps may exist at these points, and if not properly sealed, they can act as pathways for flames, smoke, and toxic gases during a fire. Inadequate sealing at the top of walls can allow a fire to spread into upper floors, rapidly increasing its reach and impact. Proper fire stopping in this area is essential for containing a fire and maintaining the building’s fire safety integrity.

4.Curtain Walls

In high-rise buildings, gaps often exist between curtain walls and the floor slabs, which can become primary channels for the spread of flames and smoke during a fire. If a fire breaks out on a specific floor, the flames and hot air can quickly rise and spread to upper floors through these gaps, creating a “chimney effect” that rapidly accelerates the fire’s spread. Therefore, fire stopping in curtain wall systems is crucial to prevent such hazards.

5.Slab Edges

Slab edges are another critical area for fire stopping, especially in high-rise buildings. These edges are typically located at the junctions between external walls, curtain walls, or other building structures. Without proper fire stopping, these areas can allow flames, smoke, and toxic gases to spread during a fire, contributing to the rapid escalation of the fire. Effective fire stopping at slab edges is essential to contain the fire and protect the building’s structural integrity.

Fire Stopping Assembly

Three Elements of Fire Stopping

1.Fire-Resistant Components

Fire-resistant components or systems within a building are designed to separate fire zones and prevent the spread of fire. These components include firewalls, fire-rated floors, fire doors, and fire windows. Firewalls and floor slabs serve to isolate different fire zones and limit the fire’s spread within the building. However, since these structures often have penetration points for pipes and cables, proper fire stopping is necessary to maintain their fire-resistant integrity. Fire doors and fire windows are designed to block flames and smoke, but the surrounding joints must also be effectively fire stopped to ensure overall fire resistance. The integrity and fire resistance of these assemblies form the foundation for the design of fire stopping, ensuring that the building’s structure can effectively prevent the spread of fire.

2.Fire Stopping Materials (e.g., Fireproof Caulking, Intumescent Materials)

Fire stopping materials are specialized products used to seal and close openings and gaps around pipes, cables, and other penetrations in fire-rated assemblies. These materials are designed to withstand high temperatures, effectively preventing the spread of flames, heat, and smoke during a fire.

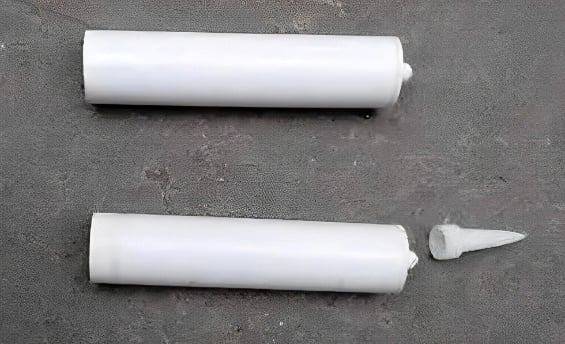

Fireproof caulking materials, such as fire sealants and coatings, are typically used to fill smaller gaps and openings. In the event of a fire, these materials expand to seal the gaps, blocking the passage of flames and smoke.

Intumescent materials are designed to expand significantly when exposed to high temperatures, filling gaps and forming a solid barrier that stops the spread of fire. These are commonly used around cable penetrations and pipe runs.

Fireproof panels, such as calcium silicate boards and rock wool boards, are ideal for sealing larger openings, offering excellent thermal insulation and fire resistance.

The selection of fire stopping materials depends on the type of penetration, the size of the opening, and the specific fire safety requirements of the building. Proper material selection ensures that the penetrations remain fire-resistant and airtight during a fire.

3.Penetrating Items (e.g., Pipes, Cables, Ducts)

Penetrating items include facilities and equipment such as pipes, cables, and ducts that pass through fire-resistant assemblies (e.g., firewalls, fire-rated floor slabs). These penetrations can compromise the integrity of fire compartments, allowing flames and smoke to spread rapidly if not properly sealed.

When pipes—such as water, gas, or ventilation pipes—penetrate firewalls or floor slabs, they must be sealed with fire stopping materials to prevent the spread of fire. Certain pipes, like plastic ones, may melt at high temperatures, requiring specialized fireproofing materials to maintain fire safety.

Cables, wires, and conduits create multiple points of penetration through fire-rated structures, and these need to be sealed with materials like fireproof sealant, intumescent compounds, or fireproof pillows to prevent fire from spreading through the openings.

Other penetrations, such as HVAC air ducts and electrical installations, must also be fire stopped with appropriate materials to preserve the fire resistance of the assembly and prevent fire from moving through these gaps.

How the Three Elements of Fire Stopping Work Together in Fire Prevention

Fire-resistant components provide the foundation for separating fire zones within a building. Fire stopping materials are used to maintain the integrity of these components by sealing penetration points, while the penetrations themselves (e.g., pipes, cables, and ducts) are the targets of fire stopping efforts. The design and application of fire stopping materials must be tailored to the specific penetrations to ensure that these openings are properly sealed during a fire.

By working together, these three elements—fire-resistant components, fire stopping materials, and the penetrations—form a comprehensive fire stopping system. This system prevents the spread of flames, smoke, and toxic gases, protecting the integrity of fire compartments and buying critical time for the safe evacuation and rescue of personnel.

Difference Between Fire Stopping and Fireproofing

Fireproofing

Fireproofing refers to the application of fire-resistant coatings, sprayed materials, or other protective substances to a building’s structural components or equipment to enhance their fire resistance. The primary goal of fireproofing is to extend the fire resistance of load-bearing structures, preventing structural failure due to high temperatures during a fire. Common fireproofing methods include the use of fireproof coatings, sprayed fireproofing materials, and fireproof boards, which insulate the structure and reduce the rate of heat transfer.

Fire Stopping

Fire stopping involves sealing gaps, holes, and penetrations (such as those created by pipes, cables, or ducts) in buildings to prevent flames, smoke, and toxic gases from spreading to other areas during a fire. As a passive fire protection measure, fire stopping focuses on closing openings and maintaining the integrity of fire-rated compartments. Materials used for fire stopping typically include intumescent products, fire sealants, and fireproof boards that can expand at high temperatures to effectively seal these penetrations.

Fire Stopping Standards and Code Requirements

General Fire Stopping Standards

1.Where is Fire Stopping Required?

Fire stopping is essential to prevent the spread of flames, smoke, and toxic gases through openings, gaps, or penetrations in a building’s structure. It is commonly applied in the following areas:

Between fire protection zones: Openings created by pipes, cables, and ducts passing through fire-rated walls or floor slabs must be sealed to maintain the integrity of fire zones.

Between floors: Vertical penetrations, such as pipes, cable shafts, and ventilation ducts, require fire stopping to prevent the upward spread of fire between floors.

Pipe and cable penetrations: All openings for pipes and cables that pass through walls or floor slabs should be sealed to stop fire from spreading through these points.

Gaps between curtain walls and floor slabs: In high-rise buildings, gaps between curtain walls and floor slabs must be sealed to prevent fire from spreading upward, often causing a “chimney effect.”

Electrical equipment rooms: Entrances, exits, and penetrations in power distribution rooms and other electrical spaces must be fire stopped to prevent fire from spreading through cable openings.

Shafts and pipe wells: Openings in cable wells, pipe wells, and equipment shafts should be sealed to stop the fire from spreading through these vertical passages.

Seams around fire doors and windows: The gaps between fire doors, windows, and walls must be sealed to prevent fire from spreading through these seams.

Fire separation of pipes and equipment: Penetrations made by smoke exhaust pipes, air conditioning systems, and similar equipment need to be blocked to prevent the spread of fire and smoke.

2.Where and How Fire Stopping Should Be Labeled

Fire stopping labels are crucial for identifying the location, materials, and construction details of fire stopping installations, ensuring code compliance and facilitating future maintenance. Labels should be placed in key areas, including penetrations through fire-rated walls, floor slabs, pipe wells, cable shafts, curtain wall-to-floor slab gaps, and equipment rooms. Each label should include information such as the type of fire stopping material used, the fire resistance rating, the date of installation, the installer’s details, and relevant codes.

Labels should be made from durable materials like sheet metal or plastic and securely fastened near the fire stopping points for easy inspection. During regular maintenance, damaged fire stopping materials must be repaired, and the labeling information updated to maintain the system’s effectiveness.

3.What Test Rating Is Needed?

The test rating for a fire stopping system depends on the type of building, fire zone requirements, and relevant codes (e.g., UL 1479, EN 1366). These tests evaluate the system’s performance in the following areas:

Fire Resistance Time: Measures how long the fire stopping system can maintain its effectiveness during a fire, typically ranging from 1 to 3 hours. High-rise buildings or densely populated areas often require a rating of 2 hours or more.

Fire Resistance Integrity: Assesses the system’s ability to remain physically intact during a fire, preventing the spread of flames and smoke.

Thermal Insulation: Limits heat transfer from the fire-exposed side, ensuring that materials in unaffected areas do not ignite due to high temperatures.

Smoke Sealing: Prevents the spread of toxic smoke through gaps, a critical feature in crowded or high-occupancy areas.

Watertightness (optional): Ensures the system can stop water or liquid from passing through, useful in flood-prone areas or where liquid containment is necessary.

Overview of Fire Stopping Standards in Different Regions

Fire stopping standards vary across regions, with the primary goal of preventing the spread of flames, smoke, and toxic gases in the event of a fire. Below is a summary of key fire stopping standards worldwide:

1.International Standards

- ISO 10295: An international standard by the ISO that outlines testing procedures for the fire resistance and compatibility of penetration sealing systems.

2.United States

- UL 1479 (ASTM E814): Tests the fire resistance and sealing capability of fire stopping systems.

- IBC (International Building Code): Requires penetration fire stopping systems to comply with UL standards.

- NFPA 101: The Life Safety Code, which includes fire stopping requirements to protect building occupants.

3.United Kingdom

- BS 476: A British Standard specifying fire resistance test methods for fire stopping materials.

- BS EN 1366-3: A European standard assessing the fire resistance and sealing performance of penetration seals.

4.Australia

- AS 1530.4: Tests fire resistance of fire stopping systems, focusing on performance in fire scenarios.

- NCC (National Construction Code): Requires fire stopping designs to meet the criteria set by AS 1530.4.

5.Canada

- CAN/ULC-S115: Canadian standard for testing fire stopping systems to ensure fire resistance and proper sealing.

6.China

- GB 50016: The building fire code, mandating fire stopping measures to ensure fire resistance in building design.

- GB 23864: Specifies technical requirements and testing methods for fire stopping materials.

7.Europe

- EN 1366-3: A European standard for evaluating the fire resistance of fire stopping systems.

- EN 13501-2: Classifies fire resistance of blocking systems, often requiring a minimum of EI 60 (60 minutes of fire resistance).

Importance of Code Compliance and Common Mistakes to Avoid

Compliance with fire stopping codes is essential for building safety, ensuring that the system effectively prevents the spread of flames, smoke, and toxic gases during a fire. Building codes specify testing standards and fire resistance requirements to guarantee that fire stopping systems perform as intended, reducing the risk of loss of life and property. Failure to install or maintain fire stopping systems in accordance with regulations can compromise their effectiveness and lead to legal liability.

In addition to enhancing safety, code-compliant fire stopping systems can lower insurance costs and improve the building’s long-term operational stability. However, several common mistakes can undermine fire stopping effectiveness, including:

- Using non-compliant or uncertified materials.

- Improper installation that doesn’t follow code requirements.

- Neglecting routine maintenance or failing to reapply fire stopping after building alterations.

- Incorrectly selecting materials for specific penetrations.

- Failing to conduct regular inspections.

- Omitting labels that mark the location and details of the fire stopping system.

Advantages of Fire Stopping Systems

Fire Compartments to Isolate Fire and Smoke

Fire stopping plays a critical role in maintaining the integrity of fire compartments. A fire compartment is an independent area within a building, designed to contain the spread of fire, smoke, and toxic gases. Its purpose is to protect other parts of the building and ensure the safety of occupants in case of a fire. Fire stopping is essential in preserving the functional integrity of these compartments, particularly by sealing penetrations such as openings, gaps, pipes, cables, and other points where fire-rated structures are breached.

Other Benefits of Fire Stopping Systems

1.Prevention of Water, Fire, Smoke, Gas, and Earthquake Issues

Fire stopping systems not only prevent the spread of flames and smoke through pipes, cables, and other penetrations but also block water from spreading during firefighting efforts. Some fire stopping materials are also waterproof, adding an extra layer of protection. Additionally, these materials can accommodate minor building shifts caused by earthquakes, maintaining the integrity of the fire stopping system.

2.Limiting Building Damage

By sealing penetrations, fire stopping systems limit the spread of fire, protecting the building’s structure and internal equipment. This reduces direct damage from the fire and preserves the effectiveness of fire compartments.

3.Containing Water Damage

Fire stopping systems also prevent water from leaking into other areas through gaps, whether from firefighting efforts or burst pipes. This helps avoid secondary damage caused by flooding.

4.Reducing Legal Liability

Installing a compliant fire stopping system reduces legal liabilities related to fire and safety hazards. It can also lower insurance premiums and mitigate the risk of compensation claims after a fire.

5.Compliance with Fire Safety Codes

Fire stopping systems adhere to international and local fire safety standards, such as UL 1479. This ensures that buildings pass fire inspections and maintain safe operational conditions.

Common Issues with Fire Stopping Installations

Common Problems Encountered During Fire Stopping Installations

1.Use of Unlisted or Unrated Fire Stopping Materials

Using untested or unrated materials can cause the fire stopping system to fail during a fire. Such materials may not provide the necessary fire resistance to effectively prevent the spread of flames and smoke, violating building codes and increasing fire risk.

2.Incorrect Installation or Inadequate Depth

Improper installation or failure to seal to the required depth can leave gaps, allowing flames and smoke to spread rapidly during a fire. It is crucial to follow the design specifications to ensure proper material thickness and correct installation to maintain fire stopping effectiveness.

3.Lack of Proper Training for Installers

Installers without sufficient training may not fully understand the correct installation procedures, leading to poor-quality fire stopping. This can result in errors such as incorrect material selection, failure to follow design specifications, and substandard construction, all of which compromise the effectiveness of the fire stopping system. Adequate training is essential to ensure the fire stopping system functions as intended.

How to Avoid These Problems

1.Ensure Proper Material Listings and Certifications

Use fire stopping materials that comply with relevant standards such as UL 1479 and EN 1366. Certified materials ensure sufficient fire resistance and effectively block the spread of flames, smoke, and toxic gases during a fire.

Before starting the project, develop a detailed list of approved fire stopping materials and ensure that they are purchased and used in accordance with building code requirements. Regularly inspect and update the material list to ensure all products used are certified and compliant.

2.Follow Installation Instructions and Seek FireSafe Expert Advice When Needed

Select the appropriate type, thickness, and installation method based on the product’s installation guidelines. Each material has unique application scenarios and requirements, so it’s crucial for builders to carefully read and follow the manufacturer’s instructions.

For complex installation scenarios or unclear fire stopping needs, consult FireSafe’s expert fire stopping professionals to ensure the system is properly designed and installed for optimal results and to avoid potential risks.

What is the Difference Between a Cavity Barrier and Fire Stopping?

Cavity Barriers: Narrowing the Gaps Between Building Elements (e.g., Cladding and Floor Slabs)

The primary function of a cavity barrier is to prevent the spread of fire, smoke, and heat through gaps between building elements, such as cladding and floor slabs. By narrowing these gaps, cavity barriers help stop the rapid propagation of fire in areas where open spaces could act as fire channels. These barriers are commonly used in building cladding systems or curtain wall systems to limit the spread of fire through narrow voids.

Cavity barriers are typically installed on building facades, within curtain wall systems, or in the gaps between cladding and floor or wall panels. Their purpose is to block the spread of flames through unenclosed spaces in the building envelope, which is particularly important in high-rise building facade systems.

These barriers are usually made from non-combustible or flame-retardant materials, such as fire-resistant rock wool or intumescent fireproofing materials.

In summary, cavity barriers are primarily used to close voids in external walls or cladding systems, preventing the spread of flames through these hidden cavities within the building envelope.

Fire Stopping

The purpose of fire stopping is to seal penetration points where pipes, cables, ducts, and other equipment pass through fire-rated partitions, preventing the spread of flames, smoke, and toxic gases through these openings and gaps. A fire stopping system ensures the integrity of the separation between different fire zones within a building.

Fire stopping is primarily used inside buildings, particularly in areas where utilities like pipes and cables penetrate walls and floor slabs. Its key function is to stop fire from spreading through these penetrations into adjacent fire compartments.

Fire stopping materials, such as fire sealants, intumescent compounds, and fire-resistant rock wool, are commonly used. These materials expand in response to high heat, effectively sealing gaps and forming a barrier during a fire.

In summary, fire stopping is mainly used to seal penetrations through fire-rated partitions, preventing the spread of flames and smoke through internal openings created by pipes, cables, and other utilities.

Importance of Fire Stopping

Critical Role of Fire Stopping in Building Safety

Fire stopping is a fundamental element of fire protection design, aimed at preventing the spread of flames, smoke, and toxic gases through penetration points such as pipes and cables. It helps maintain the integrity of fire zones within a building, delays fire spread, and ensures occupants have enough time to evacuate, thereby reducing damage to buildings and property.

Importance of Complying with Fire Safety Regulations

Fire stopping must be designed and installed in strict accordance with building codes and standards, such as UL 1479 and EN 1366, to ensure sufficient fire resistance and sealing. Compliance with these regulations is essential not only for passing fire inspections but also for reducing legal liabilities and financial risks in the event of a fire.

Monitoring and Periodic Evaluation of Fire Protection Measures

Regular monitoring and maintenance are crucial to ensure the long-term effectiveness of fire stopping systems. Aging materials, unaddressed repairs, or damage can compromise the system’s performance. Therefore, periodic inspections and evaluations of fire stopping measures are essential for maintaining building fire safety and identifying potential hazards before they become critical issues.

Conclusion

FireSafe has extensive expertise in fire stopping and passive fire protection, specializing in preventing the spread of flames, smoke, and toxic gases through highly effective fire stopping systems. FireSafe is dedicated to providing comprehensive passive fire protection solutions that ensure the integrity of fire-rated walls, floor slabs, and penetrations, significantly slowing the spread of fire and enhancing building safety.

All of FireSafe’s fireproofing materials undergo rigorous testing and comply with international standards such as UL and EN, ensuring that buildings meet strict fire safety requirements. In addition to high-quality materials, FireSafe offers professional installation services and expert consultancy to assist clients in designing, implementing, and maintaining fire stopping systems.