Calcium silicate board is composed of inorganic mineral fibers or cellulose fibers, combined with other loose short fibers as reinforcing materials. Silica and calcium compounds serve as the primary binding agents. The production process involves pulping, molding, and an accelerated curing reaction under high-temperature and high-pressure saturated steam, resulting in a durable calcium silicate sheet.

By adjusting raw material ratios and production processes, calcium silicate boards with varying characteristics can be produced to meet diverse application requirements. This adaptability ensures the material’s suitability for different working conditions. So, how exactly is a calcium silicate board prepared, and how do production methods influence its performance?

Calcium Silicate Board Production Process

After decades of development, the production process for calcium silicate boards has become standardized and streamlined. The key steps include raw material preparation, pulping, sheet molding, autoclave curing, and post-treatment. Here is an overview of the process:

Raw Material Preparation

This stage involves:

Quartz Sand Wet Grinding: To achieve the required fineness for pulping.

Quicklime Slaking: Ensures optimal reactivity.

Fiber Material Processing: Grinding and dispersing fibers to enhance uniformity.

Pulping

Fiber pulp is blended with calcium and silica-based materials in a countercurrent mixer to achieve uniform dispersion. The mixture is converted into a slurry with a consistent concentration, which is stored in a pulp tank. Some manufacturers further process the slurry using grinders to ensure even mixing of fibers and particles.

Sheet Molding

The slurry is distributed onto a conveyor blanket and dehydrated to form thin layers of blanks. These layers are wound around a molding cylinder to the desired thickness. Once the slab reaches the specified dimensions, an automated cutting system trims it, and the slabs are stacked and pressed to enhance strength and compactness.

Autoclave Curing

The slabs are placed in an autoclave, where they undergo a chemical reaction involving silica, calcium hydroxide, and water. This reaction forms Tobermorite crystals and hard calcium silicate, which are essential for the board’s strength, dimensional stability, and moisture resistance.

Drying and Post-Treatment

After curing, the slabs are dried to achieve the standard moisture content. Final quality inspections ensure that only compliant products are delivered as finished calcium silicate boards.

In this process, sheet molding and autoclave curing are particularly critical to the quality of the final product. These stages directly influence the board’s strength, expansion rate, and moisture resistance, making them the focal points for further process optimization.

The following sections will focus on these two processes, highlighting their influence on the performance of calcium silicate boards.

Blanking and molding process

After the pulping stage, the mixed slurry undergoes distribution, dehydration, and extrusion molding to form calcium silicate board blanks. The blanking process is primarily categorized into two methods, with the Copying Method being one of the most widely used.

Copying Method

The copying method, a type of wet process, was first introduced by Hatschek in the early 20th century for producing fiber cement composite materials. Over the years, this process has been refined and remains a key approach in calcium silicate board production.

The production line layout for the copying method includes three main sections:

Pulping Section: Prepares the slurry.

Mesh Box Section: Forms the blank layers.

Blank Processing Section: Converts the blanks into finished products.

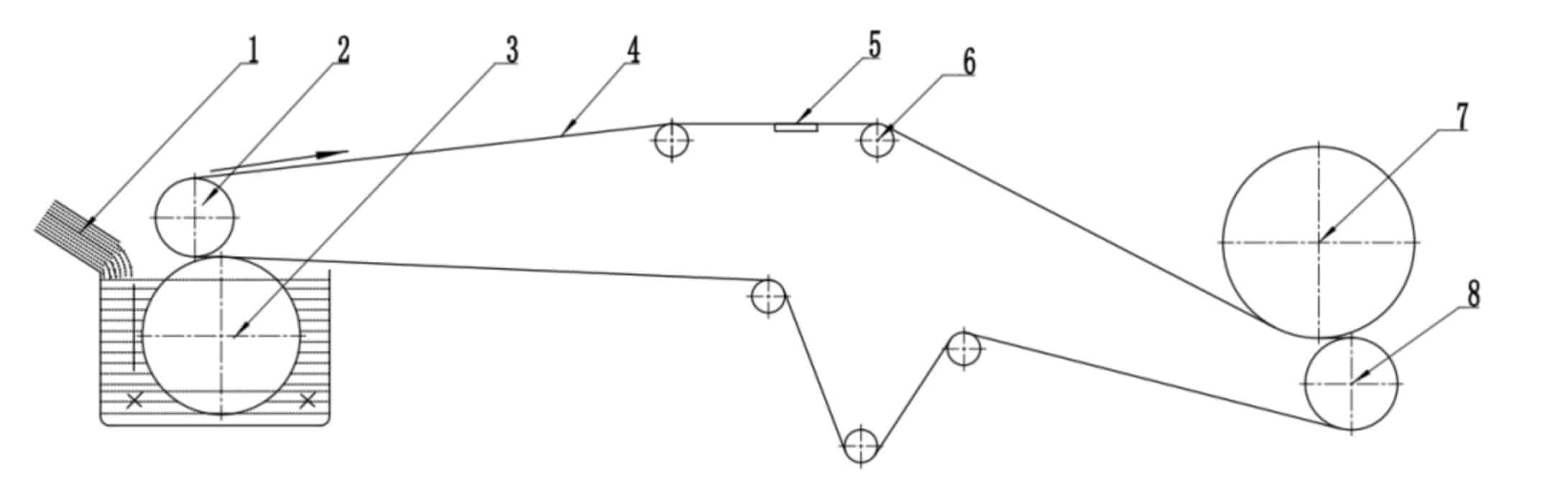

As shown in Fig. 4, the copying process begins with the net wheel mechanism, which transfers the prepared pulp to an industrial blanket. The blanket carries the pulp to the dewatering and extrusion molding sections. The molding machine’s cylinder compresses and compacts the blanks. When the industrial blanket detaches from the molding cylinder, a negative pressure is created between the blank and the cylinder surface, allowing the blank to adhere tightly to the molding cylinder. Once the desired thickness is achieved, the blank is cut and moved to the next stage of production.

Advantages and Limitations

The copying process produces calcium silicate boards with:

Uniform Layer Distribution: Ensures consistent material quality.

High Strength and Flatness: Provides excellent structural integrity and surface smoothness.

However, this method requires a large production area, is energy-intensive, and involves complex maintenance.

Flow Pulp Method

The flow pulp method, like the copying method, falls under the category of wet processes. While the overall production process is largely similar to the copying method, the key difference lies in the way the pulp is distributed. Instead of using a net wheel for pulp transfer, the flow pulp method relies on a flow pulp box as its core mechanism.

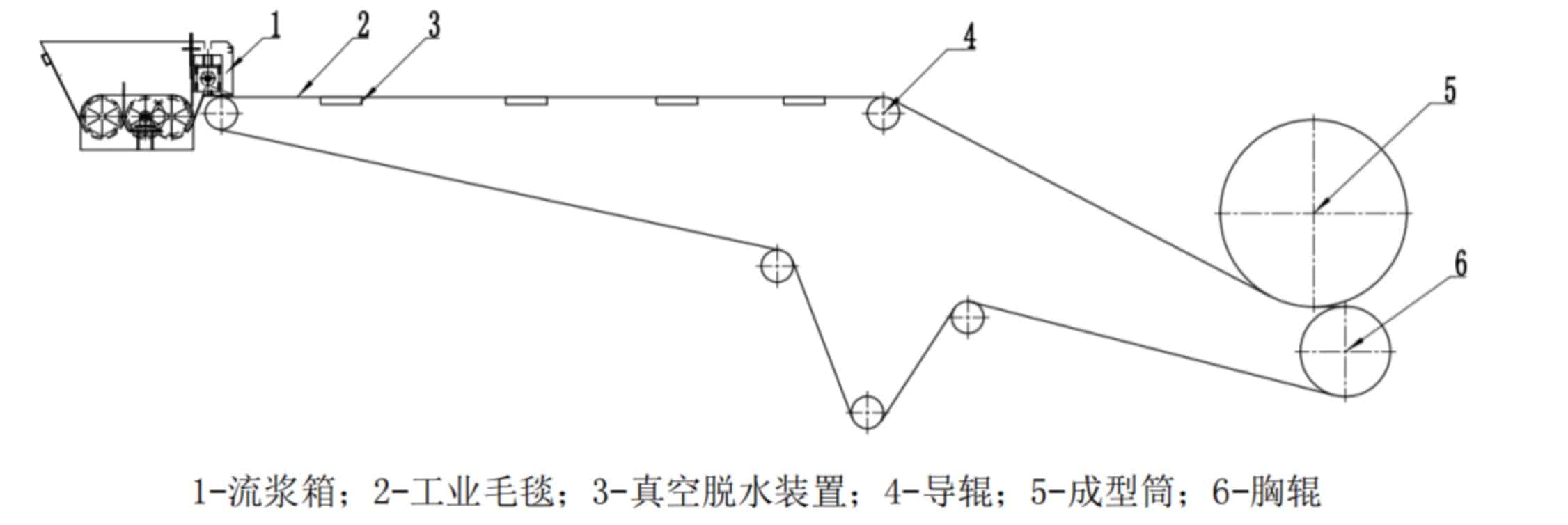

In this process, pre-mixed slurry is pumped into the flow pulp box, which spreads it evenly onto an industrial blanket. The blanket then carries the slurry through several vacuum dewatering boxes before conveying it to the calcium silicate board molding machine for extrusion, dehydration, and molding.

One of the advantages of the flow pulp box is its ability to maintain a consistent flow rate across the width of the blanket, preventing lateral flow and ensuring uniform slurry distribution. This results in a steady sizing speed across the entire width of the blanket, with no fluctuations.

The process diagram for the flow pulp method is shown in Figure 6.

As the slurry flows from the flow pulp box onto the industrial blanket, its high moisture content necessitates an increased number of vacuum dewatering suction cups in the production line. This can result in slightly reduced product flatness and strength. However, compared to the copying method, the flow pulp method requires less space and consumes relatively lower energy.

Comparison with the Copying Method

It is important to note that the flow pulp and copying methods are not interchangeable. The choice of process depends on the performance requirements of the final product and its application scenarios. Below is a detailed comparison:

| Aspect | Flow Pulp Method | Copying Method |

|---|---|---|

|

Process Type

|

Wet process

|

Wet process

|

|

Layer Thickness

|

Thicker individual layers, fewer total layers

|

Thinner individual layers, more total layers

|

|

Fiber Arrangement

|

Perpendicular fibers form a 3D reinforcing structure

|

Fibers aligned along the web direction

|

|

Flexural Strength

|

Slightly lower

|

Higher

|

|

Compressive/Tensile Strength

|

Slightly higher

|

Lower

|

|

Energy Consumption

|

Lower

|

Higher

|

|

Space Requirement

|

Smaller

|

Larger

|

|

Flatness of Finished Board

|

Slightly reduced

|

High

|

Key Factors Influencing Board Quality

Regardless of the production method, the autoclaving process plays a pivotal role. During this stage, silica and calcium components in the slab transform into chemically stable Tobermorite crystals and hard calcium silicate. The crystal content directly determines the quality of the finished board.

| Factor | Impact on Quality |

|---|---|

|

Raw Material Proportion

|

Influences the formation of Tobermorite and hard calcium silicate crystals.

|

|

Billet Production Process

|

Affects the structural integrity and uniformity of the blanks.

|

|

Autoclaving Process

|

Dictates the stability, expansion rate, and moisture resistance of the boards.

|

By fine-tuning these variables, manufacturers can produce calcium silicate boards tailored to meet specific application needs, ensuring the optimal balance of performance and efficiency.

Steam Compression Process

Hydrothermal Synthesis Method

In calcium silicate board production, calcium silicate crystals are synthesized through a hydrothermal process in a high-temperature, high-pressure autoclave. This process, known as “autoclave maintenance,” involves reacting silicon and calcium materials at 180–200°C and 1–1.5 MPa for 13–20 hours to generate stable crystals.

The hydrothermal synthesis method utilizes water as a medium for reactions in a liquid-phase chemical environment. Based on whether stirring is applied, the method is divided into two types: static and dynamic.

Static Method:

In this approach, raw materials are mixed, molded into wet slabs, and preconditioned before the autoclave stage. The preconditioning process typically involves:

Temperature: 50–70°C

Duration: 4–5 hours

Once the slab gains sufficient strength, it is demolded and sent to the autoclave for the hydrothermal reaction.

Dynamic Method:

This method involves stirring the raw materials in the autoclave during the reaction. The continuous agitation keeps solid particles suspended in the liquid phase, promoting uniform crystal growth and dispersion. It also facilitates the formation of large-diameter hard calcium silicate fibers. These fibers tend to intertwine, creating hollow secondary particles that contribute to:

High Porosity: Enhances thermal insulation.

Low Thermal Conductivity: Improves energy efficiency.

| Aspect | Static Method | Dynamic Method |

|---|---|---|

|

Process

|

Stationary hydrothermal reaction after preconditioning.

|

Reaction occurs with continuous stirring.

|

|

Crystal Growth

|

Produces smaller, less uniform crystals.

|

Promotes larger, uniformly distributed crystals.

|

|

Thermal Insulation

|

Moderate

|

High due to increased porosity and fiber entanglement.

|

|

Equipment Cost

|

Lower investment.

|

Higher investment due to complex equipment.

|

The dynamic method provides superior thermal insulation properties due to its ability to form highly porous structures, but it requires more advanced equipment and higher costs. In contrast, the static method is simpler and more cost-effective, making it suitable for projects with standard insulation requirements.

Typical Problems and Solutions in the Vaporization Process

Many experts agree that, aside from the formulation, controlling the autoclaving process is a key factor in determining the performance of calcium silicate board products. The vaporization process involves the continuous hydrothermal synthesis of siliceous and calcareous materials. During this process, new crystals form and existing crystals grow, eventually creating crystalline conidia with a spatial structure that bonds tightly to the fibers, providing strength to the board.

However, this process can also introduce structural defects that reduce the board’s strength and other physical properties. These defects primarily manifest in the following issues:

1. Internal Pressure and Structural Looseness

As the board heats up during vaporization, the water and air within the internal pores expand, generating internal pressure. At a certain stage, this internal pressure may exceed the external steam pressure.

Meanwhile, the continued growth of crystals leads to coarsening, where larger crystals form. This reduces the number of bonding points between crystals, weakening the crystalline linkage and decreasing strength. Additionally, the internal tensile stresses from crystallization pressure further weaken the structure. These combined effects can lead to structural loosening and the formation of bubbles and other defects in the board.

2.Board Edge Cracking

Board edge cracking is a significant manufacturing defect that can compromise the structural integrity of calcium silicate boards. Cracks typically appear along the edges, penetrating the entire thickness of the board, extending from a few centimeters to several inches inward. This issue primarily results from temperature and humidity differentials during the decompression stage. As the edge temperature drops below that of the interior, it creates destructive stress patterns, leading to cracking.

3.Loss of Fiber Strength

Loss of fiber strength presents a key challenge in calcium silicate board production. While transitioning from asbestos to plant or glass fibers addresses health concerns, these alternative materials face challenges during autoclaving. Although the autoclaving process is essential for creating calcium silicate hydrate bonds that improve bending strength, prolonged exposure to high temperatures and alkaline conditions can degrade the fiber integrity over time.

Manufacturing Process Optimization

To address these challenges effectively, manufacturers should adopt a comprehensive three-phase approach:

Pre-conditioning Phase

Implementing a static stop or dry heat pre-conditioning process is a crucial preliminary step. This reduces internal moisture, minimizing pressure-related stress during autoclaving and improving the board’s structural resistance.

Pressure Management

Precise control of pressure reduction, particularly during the final stages of pressurization, is vital. Premature pressure changes can compromise the board’s structural integrity before it reaches optimal strength.

Controlled Curing Process

A gentle buckling process should be used to mitigate temperature and humidity stresses. The process should be calibrated to promote moderate tobermorite formation in the hydride, with extended hydrothermal treatment reserved for panels requiring enhanced properties.

Firesafe’s Approach

As an industry leader in calcium silicate board manufacturing, Firesafe has developed proprietary processes to address these challenges comprehensively. Through advanced fiber preservation techniques and stringent quality control measures, Firesafe consistently delivers calcium silicate fireproof panels that exceed industry standards for structural integrity and performance.