Calcium Silicate Boards

Calcium silicate products are our core focus for large-scale production. Compared to other insulation and fireproofing materials like rock wool, glass wool, polyurethane, and foam glass, calcium silicate stands out with its unparalleled versatility and wide range of applications.

As China’s leading Calcium Silicate Board manufacturer, FireSafe offers a wide range of calcium silicate products to meet diverse fire protection needs. Our self-developed, low-density fireproof calcium silicate boards are lightweight and strong, delivering exceptional performance at competitive prices compared to Promat products.

- Casa

- »

- Calcium Silicate Boards

Our calcium silicate board products fire test

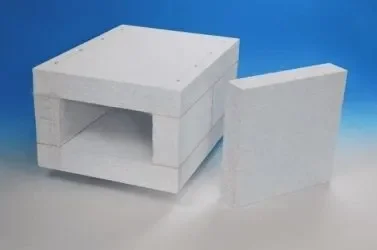

Using a 38mm thick Firesafe-900 calcium silicate board, the board is fixed onto the test furnace frame that simulates a fire temperature rise, in order to evaluate its fire resistance performance.

Complete 90-minute video of the fire resistance experiment

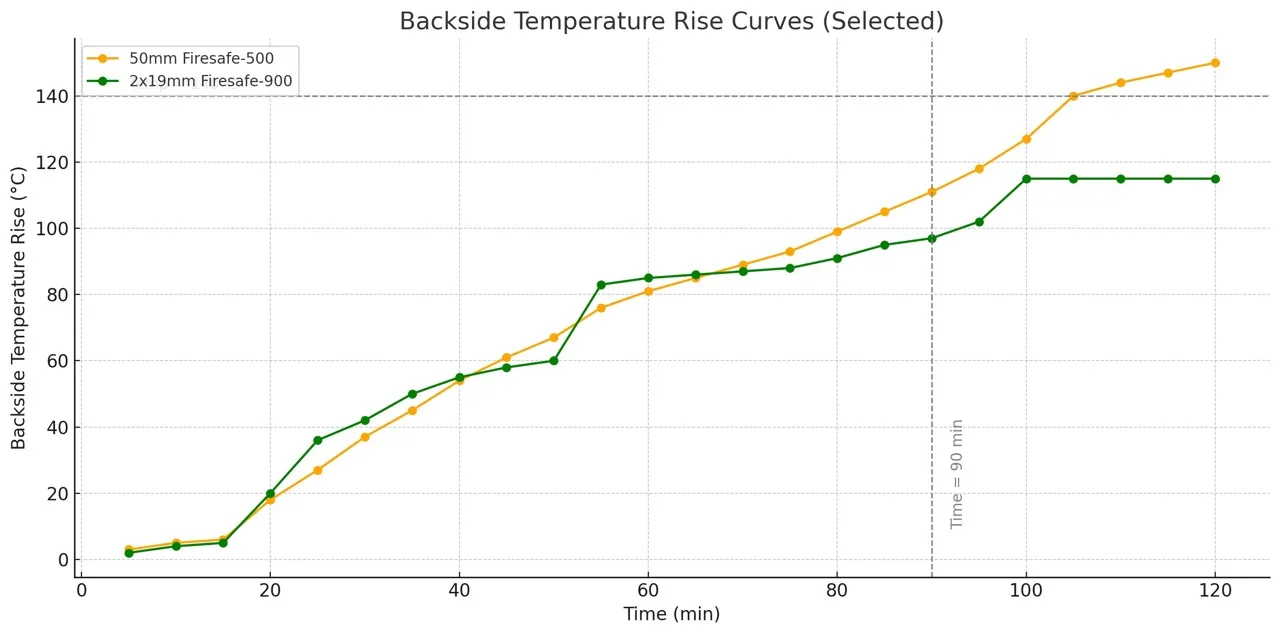

Our FireSafe 900& FireSafe 500 temperature rise curve

Calcium Silicate Boards Suppliers in China

Our Fireproof Calcium Silicate Board is a flagship product, showcasing our expertise in developing, conditioning, and enhancing hard calcium silicate and its fiber support system. While many products on the market, especially in China, claim to be fireproof calcium silicate boards, many are actually fiber cement boards. Despite containing siliceous and calcareous materials, these boards have a high cement content, which compromises their fire performance compared to true calcium silicate boards. It’s essential to note that the primary component of authentic fireproof calcium silicate boards must be hard calcium silicate.

FireSafe-500 Calcium Silicate Board

FireSafe-750 Calcium Silicate Board

FireSafe-900 Calcium Silicate Board

FireSafe-PyroFortress

FireSafe-Masterboard

FireSafe-300

General Technical Parameters

|

Indicator Project

|

Unit

|

Firesafe-500

|

Promatect-L500

|

Reference standard

|

|---|---|---|---|---|

|

Density |

kg/m3 |

500±75 |

450 |

EN 1602:2013 |

|

Thickness deviation |

mm |

±0.5 |

±0.5 |

EN 823:2013 |

|

Deviation of overall dimensions

|

mm |

±5 |

±5 |

EN 822:2013 |

|

Shear strength |

MPa |

1.5 |

/ |

EN 12090-2013 |

|

Flexural strength |

MPa |

3.8 |

1.93(Longitudinal) 1.63(Transverse) |

BS EN 310:1993 |

|

Tensile strength |

MPa |

1.262(Longitudinal) 1.035(Transverse) |

0.69(Longitudinal) 0.94(Transverse) |

BS 5669:Part1:1989 |

|

Compressive strength |

MPa |

5.51 |

3.9 |

BS 5669:Part1:1989 |

|

Thermal shrinkage |

m/mk |

-6.7×10(-7)(600°C) |

-2.5×10(-6)(600°C) |

EN 1604:2013 |

|

Thermal conductivity (25℃) |

W/(m.K) |

0.073 |

0.083 |

ASTM C518:1991 |

|

Flammability |

---- |

A1 |

A1 |

EN 13501-1-2010 |

|

Water content |

% |

2.4 |

3.3 |

ASTM C1616-2012 |

|

Asbestos content |

---- |

asbestos-free |

asbestos-free |

ISO 22262-1:2007 |

|

Flexural strength after irradiation |

MPa |

3.6 |

/ |

BS EN 310:1993 |

|

Tensile strength after irradiation |

MPa |

1.024(horizontal) 0.92 (vertical) |

/ |

BS 5669:Part1:1989 |

|

Compressive strength after irradiation |

MPa |

5.23 |

/ |

BS 5669:Part1:1989 |

Customizable and Reliable Fireproof Board

|

Thickness mm

|

Board Size

|

|---|---|

|

20,25,30,35,40,50,52 |

1200*1200,1200*2400 |

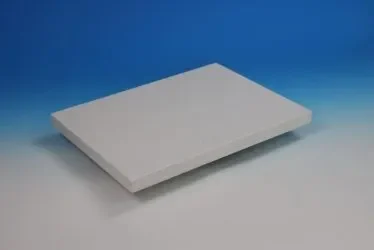

FireSafe-500 fire rated boards are designed to meet your specific needs. Available in standard sizes of 2400*1200mm and thicknesses from 15 to 55mm, these boards can be customized to fit your project requirements.

Whether you need them for a particular space or specific dimensions, FireSafe-500 boards offer flexibility and ease of installation, ensuring a smooth and hassle-free experience for your fire protection needs.

How to Choose the Right FireSafe Products

This guide helps you quickly compare FireSafe products based on their key features. Whether you need maximum fire resistance, lightweight materials, or cost-effective options, this table simplifies your decision-making process. Review the ratings to choose the best fit for your project.

Process Temperature Range

Ambient - 1000°C

FireSafe 500 Calcium Silicate Board

FireSafe 750 Calcium Silicate Board

FireSafe 900 Calcium Silicate Board

FireSafe MasterBoard Calcium Silicate Board

FireSafe-Durasteel Panel

**

*

Thermal Conductivity

*****

****

***

***

****

Light Weight

****

***

***

*

Moisture Resistance

****

*****

***

***

***

Flexural Strength

***

****

*****

****

********2

Compressive Stength

***

****

*****

*****

*****

Blast resistance

*

*

*

*

*****

Space Constraints

***

***

*****3

****

****

Transportation/Storage Cost

*

**

**

**

*****4

Ease of Installation

****

****

*****

*****

*

Longevity

*****

*****

*****

*****

****

①.With the exception of Durasteel, the main components of the other sheets are quite similar. The key difference in fire resistance lies in their density. Generally, lower density results in lower thermal conductivity, which in turn leads to a slower temperature rise on the backfire surface and extends the fire resistance limit. However, there is no significant difference in the integrity of sheets with densities of -500, -750, -900, and -Masterboard.

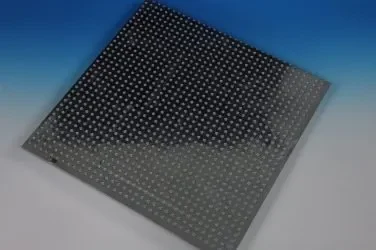

②.The special sandwich structure of Durasteel Panel makes its bending strength much higher than that of traditional calcium silicate products.

③.FireSafe-900 has the most commonly used thickness range, from 6mm to 30mm, which basically meets most of the space requirements.

④.The two perforated metal sheets should be waterproof and breathable to avoid rust.

Mechanical Properties of FireSafe-Masterboard

Thanks to the addition of special reinforcing fibers, FireSafe-calcium silicate board offers superior strength compared to other boards in its class. It features a flexural strength of over 5 MPa and a compressive strength of over 10 MPa. The board’s dense structure provides excellent riveting pull-out force, making it ideal for load-bearing and fire-resistant structural surfaces.

Precision Engineered for Easy and Safe Processing

Our boards are manufactured using over 10,000-ton presses and are fully cured in high-temperature reactors. The stable chemical structure of calcium silicate ensures that FireSafe calcium silicate board is extremely easy to process. Conventional manual and electric tools can be used for cutting, drilling, sanding, and other operations. Additionally, our boards produce minimal dust and contain no asbestos, aluminum silicate, or other harmful additives, making the processing operations safe and friendly for workers.

Advanced Insulation and Fireproofing with Calcium Silicate

In China’s thriving industrial landscape, FireSafe stands as a premier manufacturer and supplier of top-quality stainless steel duct systems. Our products are the cornerstone of durable and efficient air distribution systems, widely used in both civil and industrial buildings around the world.

Our stainless steel duct solutions offer exceptional customization, efficiency, and reliability, allowing us to meet the diverse needs of our clients while ensuring long-lasting performance and superior resistance to corrosion.

Insulating Calcium Silicate

Calcium silicate’s broad applicability is due to its rich material composition. Our products primarily use two types of calcium silicate: tobermorite and hard calcium silicate. In thermal insulation, we select these materials based on specific application requirements:

- Tobermorite Type Calcium Silicate (TP1): With a temperature resistance up to 650°C, TP1 meets ASTM C533 standards.

- Hard Calcium Silicate (TP2): This material withstands temperatures up to 1050°C, although ASTM C533 conservatively rates it at 927°C.

The difference in temperature resistance between tobermorite and hard calcium silicate lies in their structures. Tobermorite (5CaO-6SiO₂-9H₂O) has a layered crystalline structure sensitive to moisture changes; above 730°C, it transforms into wollastonite. In contrast, hard calcium silicate (Ca₆Si₆O₁₇₂) is fibrous, without crystalline water, offering a stable structure and superior temperature resistance.

Fireproof Calcium Silicate

Fireproofing applications demand more complex considerations than insulation, including factors like density, strength, thickness, fire resistance level, cost, and ease of installation. To enhance fireproof performance, we sometimes add auxiliary materials such as cement, which, rich in silica and calcium, reacts with calcium silicate to form a complex silica-calcium structure. This enables us to offer various fireproof calcium silicate board models. For top-tier fire resistance, we recommend boards made entirely from hard calcium silicate, like our -500 and -750 series.

With a firm commitment to the unique properties of calcium silicate, we have developed a comprehensive supply system centered around this material, ensuring exceptional fire protection and insulation solutions.

How to recognize real fireproof calcium silicate board ?

Density: True fireproof calcium silicate boards typically have a density between 500 and 975 kg/m³. Lower densities indicate minimal or no cement content, resulting in a predominantly porous hard calcium silicate composition.

Strength: Products with a flexural strength above 3 MPa are suitable for various passive fire protection applications, including fireproof shielding, ducts, dampers, doors, partitions, and interior walls. Standard insulating calcium silicate products cannot achieve this level of flexural strength.

If a fireproof calcium silicate board meets both the basic density and strength requirements, it is highly likely to be a true fireproof board made primarily of hard calcium silicate. Such boards can be reliably used in passive fire protection projects.

FireSafe Calcium Silicate Board Product Details

FireSafe-500 Calcium Silicate Board

Density: 500 kg/m³

Characteristics: Made entirely from hard calcium silicate stone, with no cement added. Reinforced with specific fibers, this board combines low density with high strength, making it ideal for applications requiring high fire resistance, such as fire-resistant ducts, dampers, and partition walls.

Fire Resistance:

- Up to 2 hours for fire-rated ducts

- Up to 3 hours for fire dampers (750 series)

- Up to 3 hours for fire-rated partition walls (Durasteel series)

Thickness Limitations: Standard production thickness is 20 mm or more. Sheets of 15 mm thickness can be provided by sanding, but careful handling is advised.

FireSafe-750 Calcium Silicate Board

Density: 750 kg/m³

Characteristics: Made entirely from hard calcium silicate stone with no cement added. It offers stable fire resistance and low thermal conductivity, slowing temperature rise on the non-fire-exposed surface.

Fire Resistance: Provides stable fire resistance for over 4 hours.

Thickness: Available in thicknesses as thin as 15 mm, suitable for applications requiring high fire resistance and minimal thickness, such as fire dampers rated for more than 2 hours.

Note: Pure hard calcium silicate panels have slightly lower flexural strength than cemented panels, so both strength and fire resistance should be considered when selecting the appropriate type.

FireSafe-900 Calcium Silicate Board

Density: 870 kg/m³

Characteristics: Based on the -750 series formulation, with added cement and fibers from the -500 series, enhancing mechanical strength while increasing thermal conductivity and density.

Advantages: The cement addition allows for panel thicknesses as low as 6 mm, making the -900 Series highly versatile across various systems. While thermal insulation is slightly reduced, fire resistance remains comparable to the -500 and -750 series.

Applications: Ideal for shaped structures, fireproof air ducts, walls, ceilings, and other high-demand fireproof installations.

FireSafe-Masterboard

Density: 975 kg/m³

Features: Contains a certain amount of cement and uses a conventional fiber system, making it the highest-density option in our range. With a flexural strength exceeding 5 MPa, it meets most mechanical requirements.

Advantages: Minimum thickness of 6 mm, suitable for fireproof partition walls, ceilings, and other applications. Its relatively low price helps avoid unnecessary mass overload.

Disadvantages: Slightly reduced fire resistance in terms of integrity and insulation compared to other series.

Fireproof Calcium Silicate Board Core Parameters Summary Table

This table provides a summary of the core parameters for each type of FireSafe calcium silicate board, highlighting key specifications like density, strength, thermal conductivity, and fire resistance. Use this comparison to select the best-suited product for your fire protection and insulation needs.

| Indicator Project | FireSafe-500 | FireSafe-750 | FireSafe-900 | FireSafe-Masterboard |

|---|---|---|---|---|

|

Size (mm)

|

2400*1200

|

2400*1200

|

2400*1200

|

2400*1200

|

|

Thickness (mm)

|

20, 25, 30, 35, 40, 50, 52

|

15, 20, 25

|

6, 8, 10, 12, 15, 20, 25, 30

|

6, 9, 12, 15

|

|

Density (kg/m³)

|

500

|

750

|

870

|

975

|

|

Flexural Strength (MPa)

|

3.8

|

5.3

|

11.8

|

5.0

|

|

Compressive Strength (MPa)

|

5.5

|

8.4

|

12.0

|

10.0

|

|

Thermal Conductivity (W/m·K)

|

0.073

|

0.167

|

0.23

|

0.2

|

|

Combustibility

|

A1

|

A1

|

A1

|

A1

|

|

Thermal Shrinkage (m/mK) (600°C)

|

-6.7 * 10^(-7)

|

-5.8 * 10^(-6)

|

-4.2 * 10^(-6)

|

-9.7 * 10^(-5)

|

|

Max Fire Resistance Limit*

|

4h

|

4h

|

3h

|

1h

|

|

Moisture Content (%)

|

2.4

|

1.0

|

6.0

|

6.0

|

|

Formaldehyde Content

|

None

|

None

|

None

|

None

|

- The fire resistance limit depends heavily on the test standard and system design. The limits provided here are recommended values; for specific fire resistance levels, please consult our technical team.

FireSafe Insulating Calcium Silicate Product Details

FireSafe-300 Calcium Silicate Insulation

Features: This is our primary insulating calcium silicate product line, compliant with ASTM C533 TP1 standards.

Specifications:

- Block: Standard size is 600×300 mm, with thicknesses ranging from 25 mm to 160 mm.

- Pipe: Suitable for pipes with diameters of 22 mm or larger. For pipe shells thicker than 80 mm, layering is recommended.

FireSafe-WR-300 Calcium Silicate Insulation

Features: Designed for applications requiring full water repellency, this product withstands heavy rainfall (up to 140 mm/h) with water absorption of less than 1%.

Benefits: Manufactured with an integrated water-repellent agent, WR-300 offers complete water repellency from the inside out, providing more flexibility and extended installation time. Unlike surface-treated products, WR-300 is fully water-repellent throughout the manufacturing process.

FireSafe-250 Calcium Silicate Insulation

Features: Engineered for high-temperature insulation (over 650°C), this product complies with ASTM C533 TP2 standards.

Specifications:

- Block: Available in 600×300 mm, 1200×2400 mm, and 1200×1200 mm sizes, with thicknesses from 25 mm to 100 mm.

- Pipe: Suitable for pipes with diameters of 22 mm or more; layering is recommended for shell thicknesses over 80 mm.

FireSafe-WR-250 Calcium Silicate Insulation

This is a fully water repellent product in our high temperature range, designed for high temperature environments. Currently, this series is mainly available in blocks, not yet in housings.

Insulating Calcium Silicate Product Specifications Summary

Here’s a quick overview of our insulating calcium silicate products, highlighting essential specs like density, maximum service temperature, strength, thermal conductivity, and water repellency.

| Indicator Project | -300 | WR-300 | -250 | WR-250 |

|---|---|---|---|---|

|

Density (kg/m³)

|

≤ 220

|

≤ 220

|

250~350

|

250~350

|

|

Max Service Temperature (°C)

|

650

|

650

|

1050

|

1050

|

|

Block Size (mm)

|

600*300; Thickness 25~160 mm

|

600*300; Thickness 25~160 mm

|

600*300, 2400*1200; Thickness 25~100 mm

|

600*300, 2400*1200; Thickness 25~100 mm

|

|

Pipe Size (mm)

|

Diameter ≥ 22; Thickness ≥ 25, Layering recommended if >80 mm

|

Diameter ≥ 22; Thickness ≥ 25, Layering recommended if >80 mm

|

Diameter ≥ 22; Thickness ≥ 25, Layering recommended if >80 mm

|

/

|

|

Water Repellency (%)

|

/

|

≥ 99.5

|

/

|

≥ 99.3

|

|

Compressive Strength (kPa)

|

≥ 800

|

≥ 750

|

≥ 1000

|

≥ 1000

|

|

Flexural Strength (kPa)

|

≥ 400

|

≥ 360

|

≥ 550

|

≥ 550

|

|

Linear Shrinkage After Heat Soaking (%)

|

≤ 1.8 (650°C)

|

≤ 2 (650°C)

|

≤ 2 (1050°C)

|

≤ 2 (1050°C)

|

|

Thermal Conductivity (25°C) (W/m·K)

|

0.053

|

0.055

|

0.062

|

0.060

|

|

Thermal Conductivity (100°C) (W/m·K)

|

0.057

|

0.059

|

0.075

|

0.073

|

|

Thermal Conductivity (200°C) (W/m·K)

|

0.062

|

0.065

|

0.080

|

0.082

|

|

Thermal Conductivity (300°C) (W/m·K)

|

0.069

|

0.072

|

0.087

|

0.088

|

|

Thermal Conductivity (400°C) (W/m·K)

|

0.082

|

0.084

|

0.105

|

0.103

|

|

Thermal Conductivity (600°C) (W/m·K)

|

0.120

|

0.122

|

0.132

|

0.130

|

|

Combustibility

|

A1

|

A1

|

A1

|

A1

|

|

Resistance to Stainless Steel Corrosion

|

Pass

|

Pass

|

Pass

|

Pass

|

Comparing Calcium Silicate Boards and Standard Fireproof Boards

The main differences between true fireproof calcium silicate boards and ordinary fireproof boards are fire resistance rating and density. Calcium silicate boards typically provide more than 2 hours of fire resistance integrity, though thermal insulation varies depending on board thickness and thermal conductivity. Additionally, the density of fire-resistant calcium silicate boards is generally below 975 kg/m³, whereas ordinary fireproof boards usually exceed 1000 kg/m³. These two characteristics are the most direct indicators for distinguishing calcium silicate boards from regular fireproof boards.

Suitable Fire Protection Applications for Calcium Silicate Boards

Calcium silicate boards are ideal for applications with high fire resistance requirements, especially where thermal insulation is critical. For projects requiring over 2 hours of fire resistance, calcium silicate panels are one of the few rigid materials that meet both structural integrity and insulation standards.

Is calcium silicate moisture resistant ?

Calcium silicate boards offer excellent moisture resistance, even without water-repellent treatment. After complete saturation, they retain over 70% of their original strength, and their strength remains stable once dried. This level of durability is a distinct advantage over other common fiber-based insulation materials.

Comparing Insulating Calcium Silicate with Alternative Insulation Materials

This table provides a comparison of insulating calcium silicate with other common insulation materials, highlighting key properties such as fire resistance, moisture resistance, service life, thermal insulation, workability, and cost.

| Properties | Insulating Calcium Silicate | Ceramic Fiber | Rock Wool, Glass Wool | Aerogel | Foamed Glass | Organic Insulation Material |

|---|---|---|---|---|---|---|

|

Fire Resistance

|

★★★★★

|

★★★★★

|

★★★☆☆

|

★★★★☆

|

★★★★☆

|

★☆☆☆☆

|

|

Moisture Resistance

|

★★★★☆

|

★☆☆☆☆

|

★★☆☆☆

|

★★★☆☆

|

★★★☆☆

|

★★★★★

|

|

Service Life

|

★★★★☆

|

★★☆☆☆

|

★★★☆☆

|

★★☆☆☆

|

★★★☆☆

|

★★★★☆

|

|

Thermal Insulation

|

★★★☆☆

|

★★☆☆☆

|

★★★★☆

|

★★★★★

|

★★★★☆

|

★★★★☆

|

|

Workability

|

★★★☆☆

|

★★★★★

|

★★★☆☆

|

★★☆☆☆

|

★★☆☆☆

|

★★★★☆

|

|

Cost

|

★★★★☆

|

★★★★☆

|

★★★★☆

|

★☆☆☆☆

|

★★☆☆☆

|

★★☆☆☆

|