Why Thickness Matters in Calcium Silicate Boards

Calcium silicate board thickness isn’t just a technical detail. It can significantly influence your project’s overall safety, comfort, and compliance with various building regulations. Through years of hands-on experience, we’ve seen wholesalers, contractors, and architects alike question how thickness affects fire resistance, thermal efficiency, and acoustic performance. In this guide, we’ll break down the factors shaping thickness choices and show you how to find the perfect balance for your project’s needs. Along the way, we’ll share insights from the FireSafe team, so you can make informed decisions backed by professional expertise.

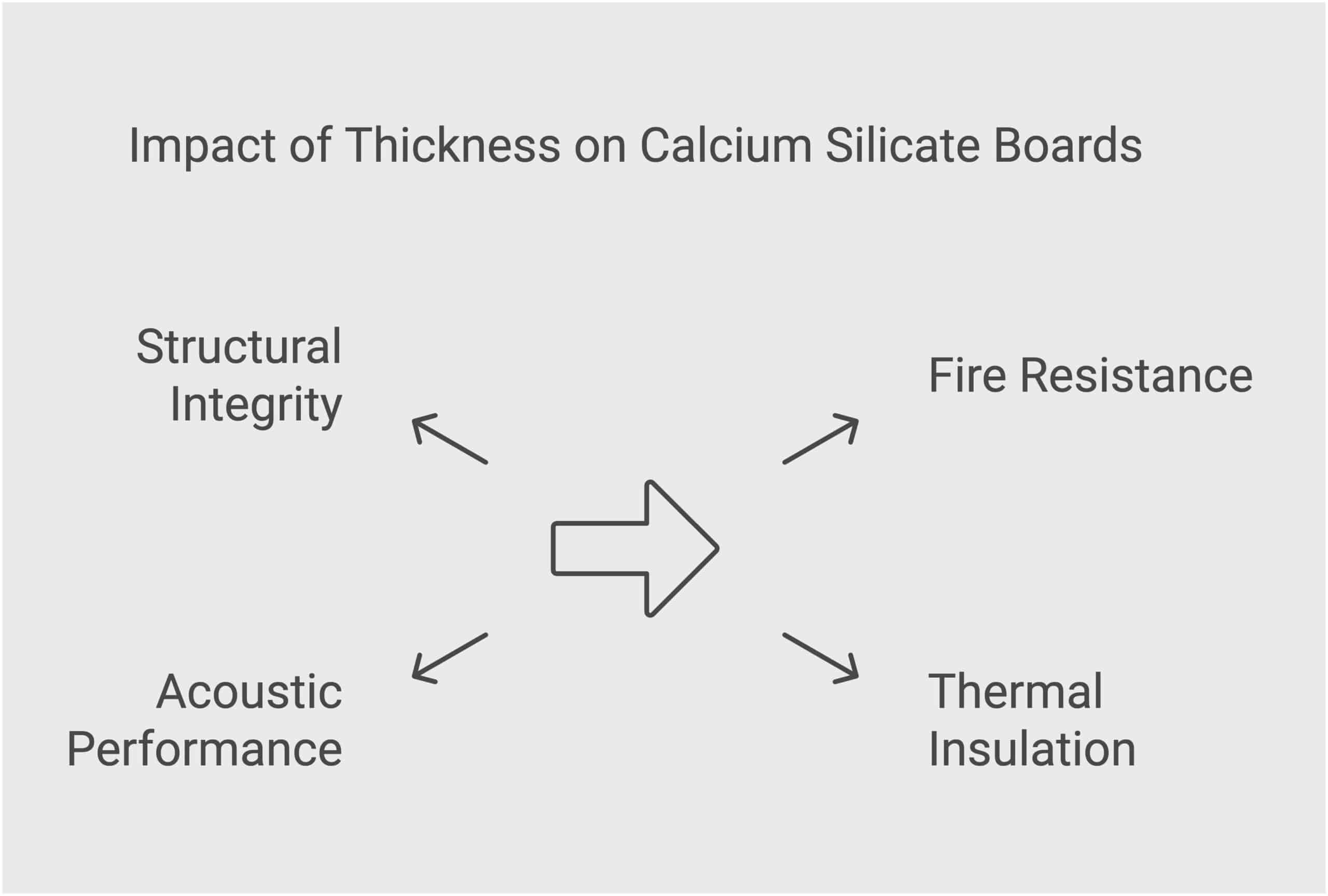

How Thickness Impacts Performance

- Fire Resistance:

Thicker calcium silicate boards typically offer enhanced fire containment. Meeting specific fire ratings helps ensure that occupants have valuable extra time during an emergency, potentially saving lives and property. - Thermal Insulation:

Beyond fire safety, thickness plays a crucial role in managing indoor temperature. A thicker board often delivers better insulation, helping maintain a comfortable climate, lowering heating and cooling costs, and improving overall energy efficiency. - Acoustic Performance:

Whether it’s a hotel, office, or educational facility, controlling noise is essential for comfort and productivity. Properly selected board thickness can reduce sound transmission, creating a quieter, more pleasant environment. - Structural Integrity:

Thickness affects a board’s strength and stability. Choosing the right thickness ensures your walls or ceilings meet relevant building standards, remain sturdy over the long term, and require fewer repairs or reinforcements.

Key Factors in Determining Ideal Thickness

Intended Use:

Are the boards for internal partitions, fire-rated ceilings, or external cladding? Each scenario may have distinct performance criteria.

Regulations and Standards:

Local and international building codes, as well as industry standards, often dictate minimum thickness requirements to ensure adequate fire safety, insulation, and acoustic performance.Consider consulting the following authoritative resources:

International Building Code (IBC): Developed by the International Code Council (ICC), the IBC provides a comprehensive baseline for building safety.

National Fire Protection Association (NFPA): The NFPA issues widely recognized fire safety codes and standards that may influence board thickness.

ASTM International (ASTM): Standards like ASTM E119 specify fire resistance testing methods for building materials.

British Standards (BS) & European Norms (EN): Organizations like BSI Group and CEN set requirements guiding construction quality, insulation, and safety.

ISO Standards: The ISO develops international standards for acoustics, energy efficiency, and more, assisting in thickness decisions.

Underwriters Laboratories (UL): UL listings and classifications confirm a product’s compliance with tested fire safety criteria.

Local Building Authorities: Always check with your local building department’s approved documents or equivalent guidelines to ensure compliance with regional requirements.

- documents or equivalent guidelines to ensure compliance with regional requirements.

By reviewing these resources and verifying with local authorities, you’ll confidently select a board thickness that aligns with all essential regulatory benchmarks. When in doubt, consult a certified professional or fire engineer for tailored advice.

Cost vs. Performance

A thicker board usually offers better performance but may also come with a higher price tag. Weighing long-term benefits against upfront costs helps you make a balanced choice.

Common Thickness Options and Applications

Use the table below as a quick reference to link thickness ranges with typical scenarios:

| Thickness Range (mm) | Typical Applications | Primary Benefits |

|---|---|---|

|

6-9

|

Standard interior walls and ceilings

|

Basic fire protection, moderate insulation

|

|

10-12

|

Enhanced fire-rated partitions, offices

|

Improved fire resistance, better acoustics

|

|

15+

|

High-demand areas (e.g., industrial)

|

Superior fire rating, stronger structure, excellent soundproofing

|

Comparing Advantages and Disadvantages of Different Thicknesses

The following table offers a clear comparison of thicker vs. thinner boards:

| Feature | Thicker Boards | Thinner Boards |

|---|---|---|

|

Fire Resistance

|

Higher fire rating, longer protection time

|

Adequate for basic code requirements

|

|

Thermal Insulation

|

Enhanced insulation, energy savings

|

Moderate insulation levels

|

|

Acoustic Performance

|

Better soundproofing

|

Less effective noise reduction

|

|

Structural Stability

|

Greater durability and strength

|

Suitable for lighter, non-structural uses

|

|

Installation & Cost

|

Higher cost, more challenging installation

|

Lower cost, easier to handle and cut

|

How to Choose the Right Thickness for Your Project

1.Identify Project Requirements:

Start by clarifying your building’s priorities: high fire protection, improved acoustics, or simply meeting standard codes. Understanding these goals steers you toward the right thickness range.

2.Check Codes and Test Results:

Review relevant standards and test results from authoritative organizations. Aligning your selection with recognized benchmarks ensures you meet or exceed required performance levels.

3.Consider Long-Term Value:

While thicker boards cost more initially, they often pay off in terms of reduced maintenance, energy savings, and fewer future modifications.

Installation and Maintenance Considerations

Thickness also influences practical, on-site factors. Heavier boards might need stronger support structures or specialized handling tools, potentially increasing installation complexity. However, the long-term durability and improved performance of thicker boards often justify the upfront investment, especially in demanding environments.

Tailored Solutions from FireSafe

At FireSafe, we know that every project is unique. Our experience in passive fire protection and material selection allows us to help you find the ideal board thickness that meets both your technical requirements and regulatory obligations. We offer:

- Expert Consultation: Personalized recommendations based on fire ratings, acoustic demands, and budget constraints.

- End-to-End Support: From choosing the right thickness to providing installation guidance and maintenance tips, our team is with you every step of the way.

For a free, no-obligation consultation or quote, feel free to reach out. FireSafe’s expertise ensures you’ll select the best possible solution, enhancing safety, comfort, and efficiency in your built environment.

Conclusion

Selecting the right calcium silicate board thickness is a critical step in achieving fire safety, thermal comfort, acoustic quality, and structural integrity. By understanding how thickness influences performance, referencing authoritative standards, and balancing cost with long-term benefits, you can make well-informed decisions that stand the test of time. With FireSafe’s professional guidance and tailored solutions, you’re well on your way to ensuring the long-term success of your construction projects.