FireSafe-PyroFortress Panel

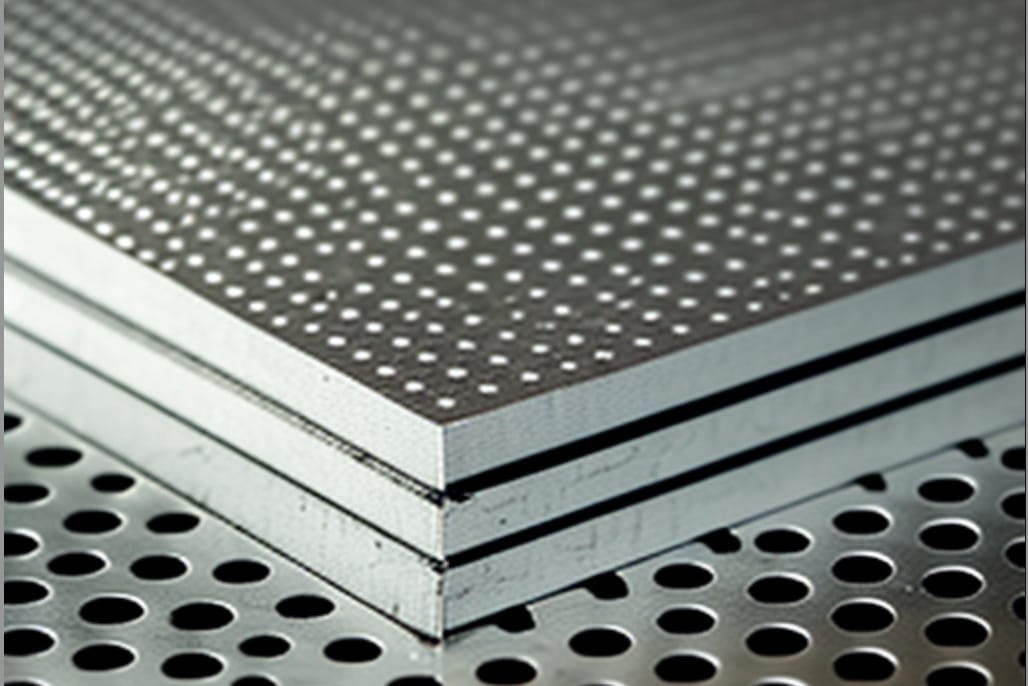

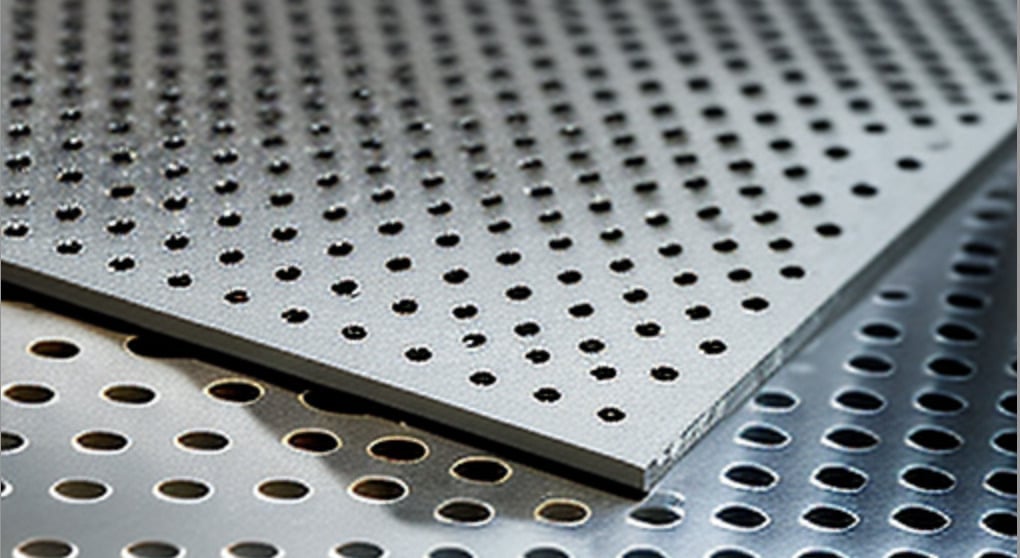

Enter the future of fire defense with the PyroFortress Panel by FireSafe, also known as the Durasteel Panel. This cutting-edge, blast-resistant composite board features a unique sandwich-like framework, with two perforated metal sheets tightly pressed on either side of a fiber-reinforced cement core. This ingenious layout ensures robustness and strength, setting the PyroFortress Panel apart from other panels on the market.

Strengthen Fire Defense with PyroFortress by FireSafe

The PyroFortress Panel, also known as the Durasteel Panel, is a robust, blast-resistant composite board designed to meet your fire defense needs. Featuring a unique structure with two perforated metal sheets and a fiber-reinforced cement core, this panel provides the strength and durability required for challenging environments.

As a trusted supplier and manufacturer of fire-resistant materials in China, FireSafe offers practical and reliable solutions. The PyroFortress Panel is an economical alternative to traditional Durasteel panels, delivering dependable performance.

Suitable for commercial, industrial, residential projects, and demanding environments such as rail and metro projects, military facilities, or petrochemical plants, the PyroFortress Panel is designed to withstand harsh conditions, ensuring safety and reliability.

Benefits of the PyroFortress Panel:

- Reliable Fire Resistance: Enhances protection for people and property.

- Blast Resistance: Withstands extreme conditions effectively.

- Durable Construction: Reduces maintenance costs over time.

- Wide Application Range: Fits various project requirements.

Choose the PyroFortress Panel for a practical, reliable solution to your fire defense needs.

Table of Contents

Excellent passive fire protection solutions

Discover the power of the PyroFortress Panel by FireSafe, an exceptional fire-resistant and blast-resistant panel designed for optimal defense in the most demanding environments. This composite board features a unique sandwich structure with a fiber-reinforced concrete core and perforated galvanized steel sheets on both sides, ensuring high durability and robustness. The PyroFortress Panel offers superior resistance to fire, blasts, water, and moisture, making it an ideal choice for any blast-resistant application.

Whether you need to fortify walls, ceilings, ducting, partitions, or E&M services, the PyroFortress Panel is the perfect solution. It efficiently protects fire services and integrates seamlessly within Durasteel systems. As a reliable alternative to the Durasteel board, the PyroFortress Panel provides comparable fire, impact, and blast resistance. Its outstanding fire resistance ensures unmatched safety, even in the most extreme conditions.

- Blast and Impact Resistance

- Water and Moisture Resistance

- Versatile Applications

Passive Fire Protection One-Stop Solution

Advantages of FireSafe Pyrofortress panel

Exceptional Impact Resistance

The core of the PyroFortress panel, a high-strength fiber concrete board, is mechanically bonded between perforated steel plates on both sides. This distinctive construction, a composite board manufactured with care, ensures the panel’s exceptional impact resistance, making it capable of withstanding various types of impact and blasting conditions. These outer facings, which can be made from galvanized steel or other steel finishes, are critical to the overall resilience of the panel. The process of crafting this panel involves pressing the steel plates into the fiber cement board, allowing for variation in the thickness and material of the surface steel plates. Consequently, different thicknesses provide differing levels of impact resistance.

Whether you’re dealing with firefighter hoses or other high-pressure situations, the PyroFortress panel stands firm. Its construction means that even under severe conditions, the durasteel systems remain resistant and robust. This panel’s adaptability and resilience mark it as a true standout, offering exceptional defense and adaptability in a range of challenging circumstances.

Fire Protection

The core material of the panel is made of silica and calcium inorganic materials, understood for their exceptional fire resistance. This creates a board capable of withstanding extreme temperatures and maintaining its structural integrity even under severe conditions. With a properly designed system, the PyroFortress panel can accomplish a fire resistance degree of more than 4 hours, and with some special items, align to 6 hrs. This degree of fire resistance supplies better defense for fire solutions as well as various other high-risk applications.

Lightweight Yet Strong Load-Bearing Structure

The PyroFortress panel is not just lightweight but also high in strength, making it an excellent load-bearing structure. It’s a great alternative to traditional reinforced concrete solid walls. For instance, to achieve a fire resistance level of 4 hours, a solid wall would need to be 240mm thick. In contrast, a 9.5mm PyroFortress panel with a 120mm x 60mm x 3mm channel steel keel and stuffed with stone wool in the middle is only 140mm thick. This design significantly reduces the weight from 600kg/m2 to 80kg/m2, making it an efficient choice for various applications.

Effortless Installation with FireSafe PyroFortress Panel

Change your building procedure with FireSafe PyroFortress Panel, a remarkable alternative to standard reinforced concrete solid walls. This panel is designed for ease of setup, calling for marginal effort from employees and also permitting a modular building and construction method.

|

Items

|

Firesafe Blast Resistant Panel

|

Reinforced concrete solid walls

|

|---|---|---|

|

Foundation |

No need |

Heavy foundation and structural support required |

|

Opening and blocking of electrical and mechanical equipment |

Requires only chainsaw and fire sealant |

Requires heavy-duty hole-digging machinery and special plugging materials |

|

Modifications |

Very easy |

Needs to be removed and redone |

|

Recycling |

Possible |

Not possible |

|

Construction |

Can work with other types of work |

Suspend other work during construction |

|

Construction speed |

4 workers can install 150 square meters a day |

Multiple workers can install 200 square meters in 1 week |

Essentially, FireSafe PyroFortress Panel is not simply a product, but a comprehensive solution that streamlines your building process while guaranteeing premium fire as well as blast resistance. The outer confrontings of perforated galvanized steel supply greater resistance, making this board with the ability of enduring the influence of firefighter hoses, leaving the systems stay resistant.

User-Friendly and Versatile

This panel is designed with straightforward features, supplying a host of advantages. It is moisture-proof, sound-insulating, and asbestos-free, ensuring safety and also convenience for customers. The panel is reinforced with special design fibers that do not have asbestos, making it a secure selection for numerous applications.

The steel layers on the panel’s surface are treated with an anti-rust finish, boosting its sturdiness. The core product, made from silica as well as calcium, guarantees the panel’s effectiveness as well as longevity. Additionally, the thick structure of the panel makes it an efficient noise insulator, with a sound depletion coefficient of 30dB or more.

FireSafe PyroFortress Panel is not only practical yet likewise maintenance-free and also space-saving. The panels are made of stable and also trusted not natural and metallic products, requiring minimal upkeep and offering a life-span of 40 years or even more.

The panel’s steel finishes are mechanically adhered, guaranteeing a solid and also long lasting framework. Whether you’re trying to find stainless-steel surfaces or various other steel coatings, FireSafe PyroFortress Panel has obtained you covered.

What is the application of pyrofortress panel

Nuclear power plants

There are various types of fireproof and blast resistant places with high requirements in the various fire protection sub-districts of nuclear power plants.

- Permeation sealing for steel pipes that require flexible sealing;

- Horizontal barriers in auxiliary shafts;

- Blast-resistant firewalls with blast-resistant fire doors, effective for up to 4 hours;

- Perimeter permeation sealing of cables leading to control rooms;

- Cross-sectional barriers in cable tunnels with blast-resistant firewalls, blast-resistant fire doors and various blocking;

- Smoke exhaust duct systems;

- Radiation sealing of steam ducts;

- Seismic gap sealing between buildings;

- Cable tunnel partition walls with transverse barriers;

- Fireproof and explosion-proof wall;

- Escape staircase fireproof spacer wall;

- Ultra-high firewall;

- Ceiling;

- Fresh air conveying duct;

- Escape corridor;

- Electrical and mechanical group fireproof sealing;

- Cable sealing;

- Tester fire protection;

Manufacturing and integrated warehouses

In industrial facilities where effective explosion protection is essential to the needs of staff, production centers, inventory and physical properties, the main areas of protection include:

- Smoke exhaust ducts;

- Explosion resistant partition walls;

- Fire partition walls;

- Jumbo compartment partition walls;

- Explosion resistant fire doors;

- Dangerous goods storage cabinet;

- Automatic rolling sliding door;

- Dry oven/painting room fireproof anti-explosion spacer wall;

- Transformer fire and explosion resistant shiel;

Oil and gas field drilling platform

The lightness and strength of PyroFortress panel, coupled with their ability to protect petrochemicals against fire, explosion, impact, fire, water and corrosion, make the blast resistant systems an ideal protection solution for offshore oil and gas production platforms as well as onshore environments with potential hazards, with specific applications as follows

- Explosion and fire protection in living areas and control rooms;

- Penetration blocking;

- Fire tongue insulation shields;

- Fire shields;

- Hazardous material storage compartments;

- Blast resistant fire walls;

- Explosion resistant fire doors;

- Pump body explosion and fire protection;

- Helicopter lift protection;

- Cooking room protection;

- Internal dormitory doors;

- Stairwell enclosures;

- Exhaust gas ventilation access;

- Emergency generator set explosion and fire protection;

- Boarding port/evacuation generator explosion and fire protection;

- Fire pump and main water loop explosion and fire protection;

- Emergency shut-off valve (ESV) system with actuator and cable explosion and fire protection;

Chemical plants

The critical areas of the petrochemical industry have very strong fire and explosion protection needs. Our explosion protection systems maximize the reinforcement and protection of vulnerable and dangerous areas to minimize major disasters, with major areas of protection including:

- Dock and quay edge protection;

- Valve actuator enclosures;

- Equipment separation facilities;

- Personnel protection compartments;

- Stairwell enclosures;

- Fuel line protection bridges;

- Escape routes;

- Transformer blast resistant fire shield;

- Fire and blast resistant walls;