High-Performance Firestop Sealant for Large Gaps and Joints

FireSafe-FSS-C

FireSafe-FSS-C Firestop Sealant is a one-component neutral silicone fire sealant designed for excellent flexibility and strong adhesion. When exposed to fire, it forms a dense mesh structure that effectively blocks flames and heat transfer. With a displacement capacity ≥25%, it is ideal for sealing large gaps in floors and wall joints.

This firestop sealant dries quickly for easy application and provides reliable protection against water, smoke, and air leaks. It is safe, environmentally friendly, non-toxic, and resistant to staining. With over 40 years of durability, FireSafe-FSS-C offers a long-lasting solution for fireproof sealing in areas with large displacements.

Firestop Sealant Performance According to GB 14683-2003

For the FireSafe-FSS-C Firestop Sealant , we measured its performance in accordance with China’s national standard GB/T 14683-2003 for silicone construction sealants. This standard provides a comprehensive evaluation of the product’s ability to perform under construction conditions, particularly its displacement capacity. By adhering to this standard, we ensure that the sealant delivers consistent and reliable results in real-world applications.

| No. | Inspection Item | Technical Index | Inspection Basis |

|---|---|---|---|

|

1

|

Appearance

|

Gray paste-like material

|

GB 14683-2003 "Silicone Building Sealant"

|

|

2

|

Density

|

Approx. 1.3 × 10³ kg/m³

|

GB 14683-2003 "Silicone Building Sealant"

|

|

3

|

Extrudability

|

≥ 80 mL/min

|

GB 14683-2003 "Silicone Building Sealant"

|

|

4

|

Surface Drying Time

|

Surface dry ≤ 3h

|

GB 14683-2004 "Silicone Building Sealant"

|

|

5

|

Sagging

|

Vertical: ≤ 3mm,Horizontal: No deformation

|

GB 14683-2005 "Silicone Building Sealant"

|

|

6

|

Elastic Recovery Rate

|

≥ 80%

|

GB 14683-2007 "Silicone Building Sealant"

|

|

7

|

Fixed Stretch Bonding

|

No damage

|

GB 14683-2008 "Silicone Building Sealant"

|

|

8

|

Cohesiveness after Ultraviolet Radiation

|

No damage

|

GB 14683-2009 "Silicone Building Sealant"

|

|

9

|

Cohesiveness after Cold Pull-Hot Pressing

|

No damage

|

GB 14683-2010 "Silicone Building Sealant"

|

|

10

|

Cohesiveness after Soaking Fixed Stretch

|

No damage

|

GB 14683-2011 "Silicone Building Sealant"

|

|

11

|

Mass Loss Rate

|

≤ 5% and no cracks

|

GB 14683-2012 "Silicone Building Sealant"

|

Application of FireSafe-FSS-C

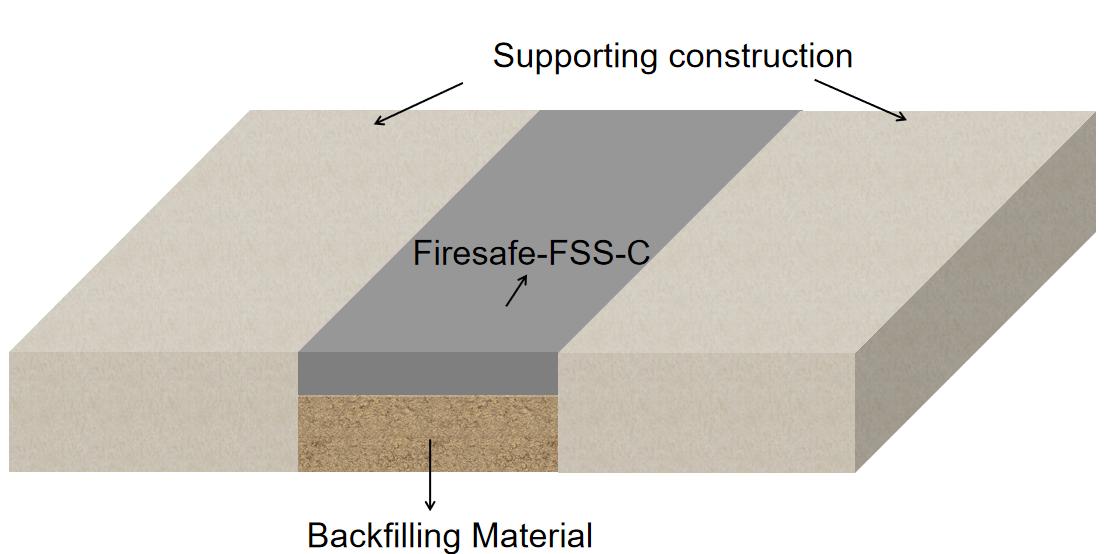

During building construction, prefabricated components like walls, beams, columns, and floor slabs are manufactured in factories and then transported to the site for assembly. These large components tend to shrink slightly, affecting joint sizes and expansion/contraction. Building deformation stress can also impact splicing joints, which typically require large displacement expansion joints.

For such applications, construction sealants must handle movement caused by temperature changes and joint expansion. Sealants for large displacement expansion joints need the following key features:

- Waterproof, airtight, and insulating with strong adhesion

- Excellent weather resistance

- High elasticity and displacement capacity to meet movement demands

To address these needs, FireSafe developed the FSS-C Firestop Sealant, perfect for fireproof sealing in large displacement gaps on both horizontal and vertical surfaces, such as floor and wall joints.

Superior Fire Resistance for Critical Sealing

In assembled buildings, a qualified and effective firestop system is crucial. In the event of a fire, a reliable fireproof sealing system can slow the spread of flames and reduce smoke concentration, giving people more time to escape and extinguish the fire. The fire resistance of joint sealants is critical to the overall performance of the firestop system. Sealants must not only be flame retardant and self-extinguishing, but also withstand high temperatures without ashing or breaking down. This ensures that the sealant continues to protect the integrity of building components during a fire.

FireSafe-FSS-C Gap Sealant offers exceptional fire resistance. Below, we provide key performance data for reference.

| No. | Inspection Item | Technical Index | Inspection Basis |

|---|---|---|---|

|

1

|

Fire Resistance

|

Fire Integrity ≥ 3h, Fire Insulation ≥ 3h

|

BS 476: Part 20: 1987 (BS EN 1363: Part 1: 2012)

|

|

2

|

Combustion Performance

|

Not lower than HB level

|

IEC 60695-11-10:2013

|

Environmental Resistance Performance

| No. | Inspection Item | Technical Index | Inspection Basis |

|---|---|---|---|

|

1

|

Water Resistance

|

≥ 3 d, no swelling, no cracking

|

GB 23864-2009 "Fireproof Sealing Material"

|

|

2

|

Alkali Resistance

|

≥ 3 d, no swelling, no cracking

|

GB 23864-2009 "Fireproof Sealing Material"

|

|

3

|

Acid Resistance

|

≥ 3 d, no swelling, no cracking

|

GB 23864-2009 "Fireproof Sealing Material"

|

|

4

|

Moisture and Heat Resistance

|

≥ 360 hours, no cracking, no pulverization

|

GB 23864-2009 "Fireproof Sealing Material"

|

|

5

|

Freeze-Thaw Cycles

|

≥ 15 cycles, no cracking, no pulverization

|

GB 23864-2009 "Fireproof Sealing Material"

|

|

6

|

Expansion Performance

|

≥ 300%

|

GB 23864-2009 "Fireproof Sealing Material"

|

Instructions for use

Packaging and Storage

This product is packaged in 300mL per tube, with 20 tubes per carton. Storage conditions should be maintained between 3-35°C.

Installation Instructions

- Clean the opening; ensure the joint surface is dry, dust-free, and grease-free.

- Fill the holes or gaps with mineral wool or other backing materials.

- Apply the product at the specified thickness over the backing material.

- Smooth the surface using appropriate tools.

- If necessary, install identification stickers next to the fireproof sealing area for easy identification during future maintenance.

Recommendations for Use

- Use mineral wool (non-combustible) as the backing material, with a recommended density of over 100kg/m³.

- Choose the appropriate amount of product based on the seam width and required fire resistance rating.

- For walls, apply the product on both sides of the backing material; for floor slabs, apply on one side only.