What are Fire Resistant Panels?

Fire resistant panels are constructed from non-combustible materials designed to contain fires and prevent heat transfer. Typically made with a core of mineral fibers or calcium silicate, these panels are essential for safeguarding buildings by limiting fire spread and maintaining structural integrity.

Fire resistant panels are essential components in safeguarding lives and property during fire emergencies. These panels are designed to contain fires and minimize heat transfer, thereby protecting the building’s structural integrity and enabling safe evacuation.

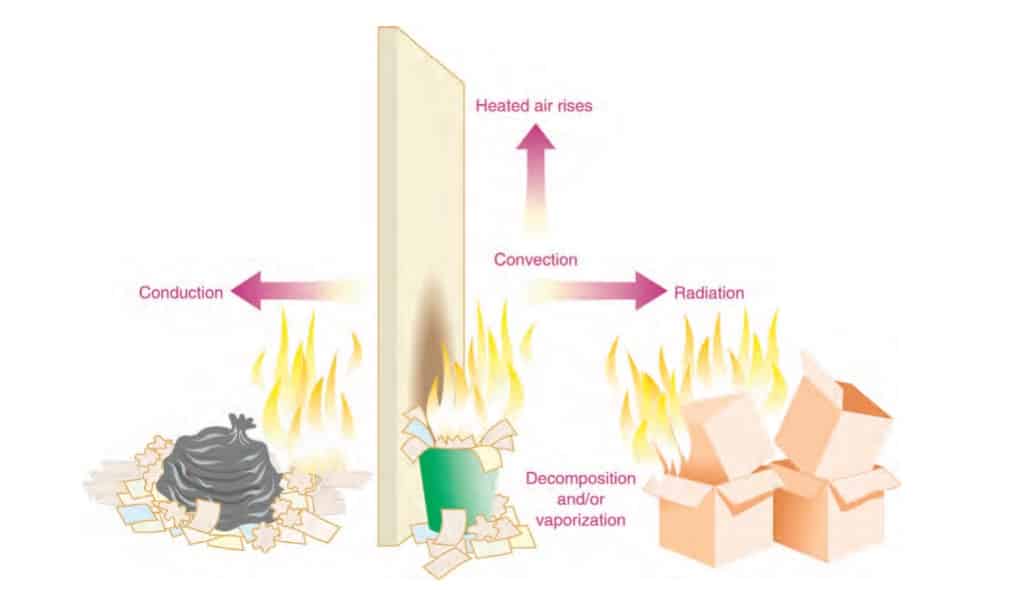

When a fire breaks out, it’s vital to keep the flames contained and maintain the strength of load-bearing structures. Fire resistant panels excel in this role, offering superior resistance to heat and fire radiation. With low thermal conductivity and high heat absorption, these panels ensure that the temperature on the unexposed side remains low, even in intense fires.

Beyond their insulation performance, fire resistant panels also provide integrity (E), acting as a barrier that prevents flames and toxic gases from penetrating, thus stopping the fire from spreading further.

Due to their exceptional properties, fire resistant panels are used in various applications, such as:

- Creating fire compartments within buildings

- Providing protection for load-bearing structures

- Enclosing electrical wiring

- Fire-rated ducts

In each of these scenarios, fire resistant panels serve a critical purpose: containing fire and heat on one side while keeping the other side cool and unaffected.

By effectively containing fires, these panels minimize the spread of fire throughout the building, limit temperature increases on structural components, and ensure the safety of occupants and first responders.

How To Determine The Fire Resistance?

1.Evaluating Fire Resistance Performance

Fire resistance is evaluated based on several key criteria, as defined by European test standards. These criteria include:

Load-bearing capacity (R): The panel’s ability to support weight without collapsing under fire conditions.

Integrity (E): The panel’s ability to prevent flames and hot gases from passing through.

Insulation (I): The panel’s effectiveness in limiting temperature increases on the unexposed side, ensuring it doesn’t rise more than 140°C on average or 180°C at any specific point.

Fire resistance is measured in minutes and classified in intervals of 30 minutes. For example, a load-bearing steel structure with a fire endurance of at least 90 minutes is classified as ‘R 90’. Similarly, a partition wall that maintains its structural stability and low temperature for 60 minutes is designated as ‘EI 60’.

2.Assessing Combustion Performance

Materials used in fire resistant panels are also classified based on their reaction to fire, which indicates their potential to contribute to a fire. These classes range from A1 and A2 (non-combustible materials) to lower ratings like B and C. FireSafe’s fire protection boards meet the A1 classification, ensuring the highest level of safety and fire resistance.

How to Choose Fire Resistant Panels?

Selecting the right fire resistant panel depends on several factors, including thermal insulation, heat absorption, and the material’s behavior during a fire. Panels like FireSafe’s calcium silicate boards are renowned for their thermal stability, maintaining fire resistance even under extreme conditions.

Different types of fire resistant panels are available for specific applications, each with unique benefits such as ease of installation, impact resistance, and weather durability. It’s crucial to choose a panel that not only meets fire resistance standards but also suits the specific needs of your project.

Comprehensive Passive Fire Protection: More Than Just Panels

Fire resistance is not just about the panel itself; it involves a comprehensive system. The effectiveness of fire resistant panels depends on proper installation, including correct fixings, spacings, and joint treatments. Ignoring installation guidelines can severely compromise the panel’s performance during a fire.

FireSafe’s calcium silicate boards are designed for optimal thermal stability and mechanical strength, and they can typically be installed with staples, eliminating the need for joint treatment. This simplicity reduces installation time and costs, while enhancing overall reliability.

How Long Fire Resistant Panel Could Use?

While the primary function of fire resistant panels is to protect against fire, they must also be durable under various conditions, such as exposure to heat, cold, moisture, and mechanical impact. Most of FireSafe’s products boast a 40-year durability classification for internal applications, and some are even suitable for semi-exposed applications.

As fire protection technology advances, FireSafe continues to innovate, developing thinner, lighter, and more durable solutions to provide long-lasting security and peace of mind.

FAQ

What is Calcium Silicate Board?

Calcium silicate board is an inorganic building material made from a mix of silica sand, quartz powder, fly ash, Portland cement, lime, reinforcing fibers, and water. These components are formed into boards and treated with high-pressure and high-temperature processes. Known for its superior fire resistance, moisture resistance, and durability, calcium silicate board is widely used in construction as an alternative to gypsum and asbestos cement boards.

For more detailed information, you can read the full article what-is-calcium-silicate-board.

What Is the Best Fire Protection Board?

The best fire protection board combines superior fire resistance, durability, and moisture resistance. Calcium silicate boards, especially those made with xonotlite, are top choices due to their non-combustible nature, excellent thermal insulation, and high mechanical strength. These qualities make them ideal for passive fire protection in both residential and commercial buildings. FireSafe’s calcium silicate boards stand out for their exceptional high-temperature resistance and long-lasting durability, making them a leading option for fire protection.